The Research Group of Metal Matrix High Temperature Lubricating Materials of the Lanzhou Institute of Chemical Physics (LICP), CAS, investigated the friction and wear of the thermal-oxidized (TO) Ti3SiC2. The results indicated that TO–Ti3SiC2 showed excellent tribological performance.

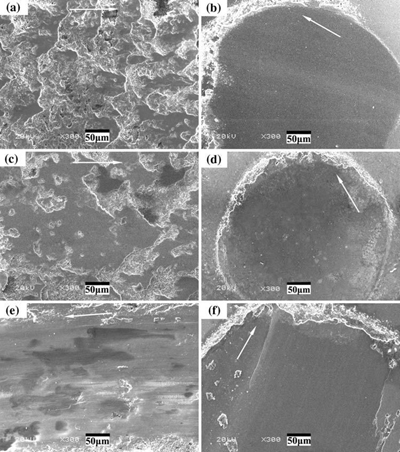

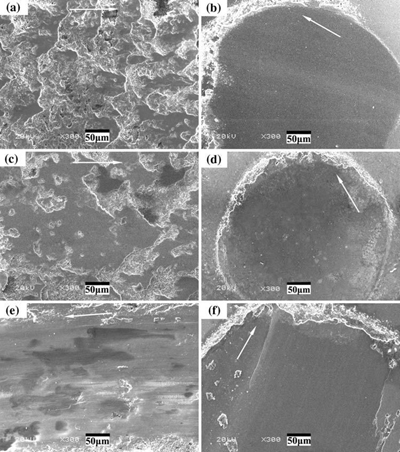

Ti3SiC2 was thermally oxidized (TO) at 1,000℃ for 10 h. An oxide scale of ca. 25 um was composed of two sub-layers with different compositions and microstructures. The microhardness of TO–Ti3SiC2 is as high as 10.28 GPa. The tribological behavior of Ti3SiC2 and TO–Ti3SiC2 sliding against Si3N4 at 25 and 600 ℃ was investigated. Results showed that TO–Ti3SiC2 exhibited better tribological performance than Ti3SiC2 at both 25 and 600℃ in air. It is the tribological behavior of TO–Ti3SiC2 is controlled by two competitive wear mechanisms, i.e., fracture and spalling of grains followed by severe material transference, in the tribo-induced oxide layer. The oxide scale formed through the thermal oxidization of Ti3SiC2 significantly improved the tribological performance of Ti3SiC2.

In recent years, many researches have been dedicated to the thermal oxidation (TO) of Ti3SiC2, for example, the characterization of the microstructure of the oxide scale on Ti3SiC2, etc.These researches have deepened people’s understanding of the performance of Ti3SiC2 and expanded the application of Ti3SiC2. However, little attention has been paid to the tribological performance of the TO–Ti3SiC2.

The research has won support from the National Natural Science Foundation of China, the West Doctor Program and the Knowledge Innovation Program of the CAS. The research has been published in the recent issue of Tribol. Lett. (Tribol. Lett. (2010) 37:59–67).

Abstract of the paper published inTribol. Lett.

Typical SEM morphologies of worn surfaces of TO–Ti3SiC2 (a) and Si3N4 (b) at 1 N; TO–Ti3SiC2 (c) and Si3N4 (d) at 3 N; TO–Ti3SiC2 (e) and Si3N4 (f) at 5 N at 600℃