| News |

| ・Events |

| ・Int’l Cooperation News |

| ・Upcoming Events |

| Location: Home>News>Events |

| Tribological Behaviors of DLC Coatings Lubricated With Benzotriazole-Containing Borate Esters |

| ||||||

|

|

Diamond-like carbon (DLC) coating is one of the most promising functional coatings. It possesses many important characteristics such as extremely high hardness, high thermal and chemical stability, and excellent tribological properties. Research reveals that DLC thin films possess excellent friction reducing and anti-wear properties. However, it is also found that conventional lubricants used in friction pair are not suitable for DLC friction pair. Or it can be said that with traditional lubricating oil the advantages of DLC friction pair are not fully used. The research group headed by Prof. XIA Yanqiu of the State Key Laboratory of Solid Lubrication of the Lanzhou Institute of Chemical Physics (LICP), CAS, has synthesized some additives, such as benzotriazole-containing borate esters and containing boron rare earth additives etc. and added them respectively into poly-alpha-olefin (PAO). Researchers investigated the tribological behaviors of different DLC coatings with containing borate esters and containing boron rare earth additives, at the same time. molybdenum dithiocarbamate (MoDTC) were used as the comparison.

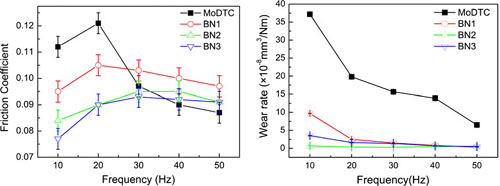

Friction coefficient and volume wear rate of Ti/Al-DLC coating at 80 N for 30 min (Image by XIA Yanqiu et al.)

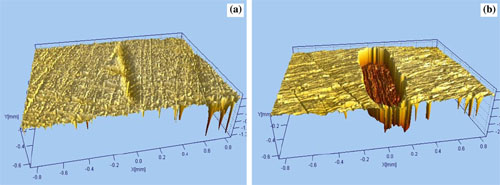

3D profiles of the wear tracks of the Ti-DLC coating lubricated with PAO-BN1 (a) and PAO-MoDTC (b) at 20 N and 50 Hz for 30 min (Image by XIA Yanqiu et al.) The results show that the synthesized benzotriazole-containing borate esters and containing boron rare earth additives etc. had better friction-reducing and anti-wear abilities for the Ti-DLC coating/steel sliding pair properties than MoDTC. The tribochemical characteristics and action mechanisms of the additives lubricated with the DLC coatings were discussed too. The research has provided technological support for the application of DLC materials in automobile engines, bearing and vulnerable friction pair material. The work has received support from the National Natural Science Foundation of China. The findings have been published in Tribol Lett (2011, 41, 247–256; 2011, 41, 425–434). |