As a potentially powerful manufacturing tool, 3D printing has attracted quite a bit of attention.

In cooperation with the University of Western Ontario in Canada, the group for surface and interface of materials at the State Key Laboratory of Solid Lubrication of Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) has developed an initiator integrated 3D printing approach (i3DP) to enable post-printing surface modifications for various applications. Various functional complex structures, including superhydrophili, superhydrophobic, biocompatible, antibacterial, polymeric and metallic structures, can be achieved. With the newly developed technique, researchers are capable of fabricating flexible conductors, ultra-light metal foam, and even pouring water into a sieve which can not be achieved using the traditional method.

The technique shows great potential in controlled functionalization of surfaces printed by 3D printing technology and fabrication of functionalized structural materials. It is expected to speed up the application of 3D printing technology in bionics, biomedical sciences, flexible electronics and so on.

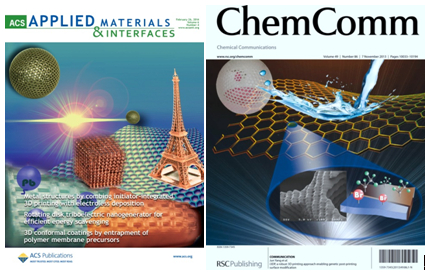

The paper was published in ACS Appl. Mater. Interfaces(2014, 6, 2583), Chem. Commun.(2013, 49, 10064) andJ. Mater. Chem. B (2013, 1, 6644). The papers published in ACS Appl. Mater. Interfaces (2014, 6, 2583) and Chem. Commun. (2013, 49, 10064) have been selected as the cover paper and highlighted by the Chemistry World (http://www.rsc.org/chemistryworld/2013/09/3d-printing-ink-surface-modification) recently. Supported by the Oversea Project of CAS, Dr WANG Xiaolong, the first author of the paper, has gone to University of Western Ontario in Canada to pursue further study.

Covers of ACS Appl. Mater. Interfaces (2014, 6) and Chem. Commun. (2013, 49)