Solar-energy utilization is realized through solar collectors. With the development of industrial utilization of solar energy and solar energy buildings, the demand of flat plate solar collectors is growing considerably.

The solar energy absorbing coatings are the key parts in solar collectors. However, current methods used to prepare solar energy absorbing coatings, including the coating method, electro-deposition method, sol-gel method, magnetron sputter method and so on, all have certain disadvantages, namely environmental pollution, limited application areas, harsh preparation conditions, high cost, poor weather resisting property and so on . Hence, to develop greener and cheaper way to prepare solar energy absorbing coatings has become a challenge in the flat plate solar collectors area.

|

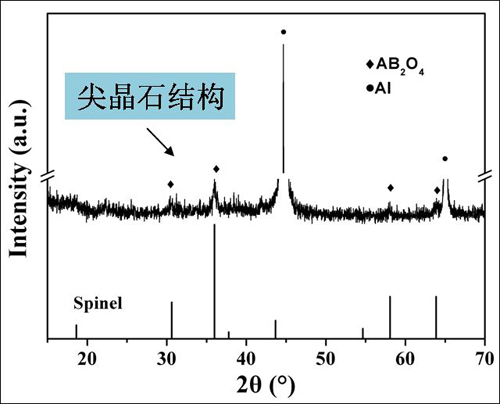

| XRD of the spinel-type ceramic heat-absorbing coatings (Image by LIU Gang et al.) |

Researchers at the Lanzhou Institute of Chemical Physics of the Chinese Academy of Sciences (CAS) have fabricated high temperature-resistant ceramic nano heat-absorbing coatings with spinel type structure. Using more than 2 kinds of semi-conduct spinel-type transitional metal oxides, they have coated sol liquid on metal matrix using dip coating or roller coating method. Then the metal quickly sintered under the influence of catalysts.

The crystallization temperature of the as-prepared spinel-type ceramic heat-absorbing coatings can be as low as 460℃ and the crystallization time can be shortened to 10 minutes. All of these have made the industrial preparation of spinel-type ceramic solar energy-absorbing coatings possible. By adding a layer of anti-reflective coating on the solar energy-absorbing coating, the absorbing rate can reach 0.95 and the emission ration is 0.05. The coatings can endure high temperature (>1000℃) and exhibit good anti-oxidation and weather resisting properties.

As the thickness of the coatings is less than 200 nm, the stress change between the metal matrix and ceramic coatings can be eliminated, which can guarantee a firm adhesion between the metal matrix and ceramic coatings.

Compared with magneto-controlled sputter coating method, the new technique does not require harsh preparation conditions and is low in cost. And the color of the coatings can be changed as well.