| News |

| ・Events |

| ・Int’l Cooperation News |

| ・Upcoming Events |

| Location: Home>News>Events |

| Progress on Tribological Behavior of Polyimide Under Harsh Conditions Made by LICP |

| ||||||

|

|

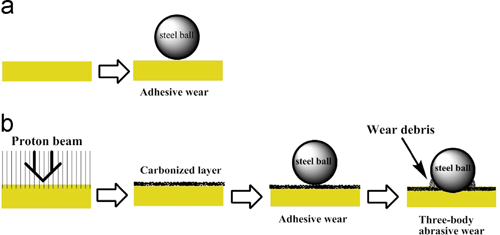

As one of the most common engineering materials, polyimides and polyimide composites presenting with excellent advantages, such as mechanical properties, low coefficient of linear expansion and cost-effectiveness, occupy a considerable market share nowadays. However, polymers are vulnerable to be influenced by harsh environment, which will affect the life-span and reliability of mechanical parts. The research group for polymer self-lubricating composite materials at the Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) has been engaged in the study on the tribological behavior of polyimide for years and achieved a series of progress recently. They have synthesized a series of thermo setting polyimide (TPI) oligomers with different calculated number-average molecular weights (Mn) and investigated the effect of Mn on tribological properties under high temperature. The results show that at room temperature, TPI specimens displayed inferior wear rate in contrast with YS-20 (thermoplastic polyimide) under higher sliding velocity. However, under 300℃,TPI specimens could hold a steady-state tribological performance, which was pre-eminent than YS-20. Adhesive wear dominated the whole process of YS-20. Wear mechanism of TPI specimens changed from fatigue wear to adhesive wear along with the temperature increase, under diverse temperatures. Especially for TPI-3 (Mn:3000), the transition between fatigue and adhesive wear was distinctive. The transition from slightly adhesive to seriously adhesive wear was clear for TPI-5 (Mn:5000) and TPI-7 (Mn:7000). The adhesive wear aggravated as Mn increases. The transition from slightly adhesive to seriously adhesive wear appeared at low temperature for TPI-7 thanTPI-5, owning to the effect of Mn of PIoligomer. The calculated Mn of PIoligomer was one of the significant factors which affected Tg, mechanical and tribological properties. Apparently, TPI-3 showed the best performance under high temperature, and thermo plastic polyimide could not hold a steady state under the same temperature. The work has been published in Tribology International (Tribology International78(2014)47–59). Polymers are widely applied in space systems as thermal blankets, structural materials, thermal control coatings, adhesives and solid lubricants owing to some unusual properties, such as high strength-to-weight ratio, good mechanical properties, excellent thermal stability, and chemical inertness. At present, to the author's knowledge, there are no reports on revealing the relationship of proton irradiation depth and the evolution of wear mechanism. The group has investigated the effect of 25keV proton irradiation with fluence of 2.25×1017 ion/cm2 on the structural and tribological properties of polyimide blocks in a ground-based simulation facility. The experimental results indicated that the proton irradiation induced bond breaking to form the carbon-enriched structure on polyimide surface, and then increased the surface hardness and the surface energy. The irradiation depth was restricted within 514nm from the surface by TRIM simulation.

The schematic of the evolution process of wear mechanism.(Image by WANG Qihua et al.) The carbonized layer induced by irradiation was worn out in friction test, which was proved through Raman spectra analysis of the wear track. Proton irradiation increased the initial friction coefficient and decreased the steady friction coefficient of polyimide. In the initial stage, the friction coefficient was closely related to surface hardness of material, and the main wear mechanism was adhesive wear. In the steady stage, the main wear mechanism was three-body abrasion wear, three-body abrasion and the low surface energy could reduce the wear rate and the friction coefficient. The work has been published in Wear(Wear316(2014)30–36). It is hoped that the work can provide theoretical guidance for the application of polyimide under harsh conditions. The above work has received support from the National Science Foundation for Distinguished Young Scholars of China. |