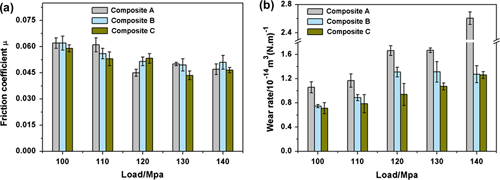

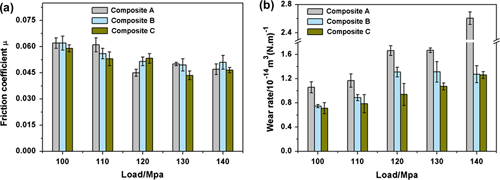

Owning to its outstanding self-lubricating property and high strength of the made polymer composites, hybrid PTFE/Nomex fabric is widely used. However, the inertness of Nomex fiber and PTFE fiber surface hinders the tight adhesion between fabric and adhesive resin, which influences the antiwear performances of the hybrid PTFE/Nomex fabric/ polymer composites. Filler filling and surface modification of the fabric are the two universal ways adopted to improve the tribological property of the fabric composites. Nevertheless, incorporation of lubricant additives in polymer matrix contributes to the friction reduction of polymers at the cost of slight deterioration in the bonding strength between polymer matrix and fabric. It is well-known that surface treatment of fabric by plasma etching endows fibers with high roughness, surface-to-volume ratio and increased activity, which facilitate the adhesion between fabric and polymer matrix through mechanical interlocking and chemical bonding. The research group for composite lubricating materials at the Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) has studied the combined effect of air-plasma treatment and lubricant filling on the dry sliding wear behavior of hybrid PTFE/Nomex fabric/phenolic composite. In the study, hybrid PTFE/Nomex fabric was firstly treated by air-plasma to improve the fabric–resin adhesion and tribological properties of hybrid PTFE/Nomex fabric/phenolic composite. Subsequently, polyfluo wax (PFW) was employed as lubricant filler to further improve the anti-wear property of air-plasma treated fabric composite.  Friction coefficient (a) and wear rate (b) of composite A (untreated fabric composite), composite B (air-plasma treated fabric composite), and composite C (PFW filled air-plasma treated fabric composite) as a function of applied load. The sliding speed in the tests was 0.26 m/s. (Image by ZHANG Zhaozhu et al.) The results of wear tests showed that, compared to untreated fabric composite and air-plasma treated fabric composite, PFW filled air-plasma treated fabric composite exhibited enhanced tribological properties, characterized by low wear rate, smooth worn surface, and continuous transfer film formed on the corresponding counterpart pin. The antiwear property and load-carrying capacity of the fabric composites followed the order of PFW filled air-plasma treated fabric composite > air-plasma-treated fabric composite > untreated fabric composite. The optimum power of air plasma treatment and content of PFW were 100W and 2 wt%, respectively. It was the air-plasma treatment resulting in improved interfacial bonding between fabric and resin combined with the self-lubrication of PFW that made the fabric composite exhibited the pronouncedly improved tribological property. The study is expected to extend the application of fabric composites. And the findings have been published in Composites Science and Technology(100 (2014) 204–211) . |