Researchers of the Lanzhou Institute of Chemical Physics pf the CAS have fabricated A high-temperature self-lubricating composite NiAl–Cr–Mo–CaF2 using the powder metallurgy technique and investigated the tribological behavior of the composite at a wide range of temperatures (room temperature to 1000℃).

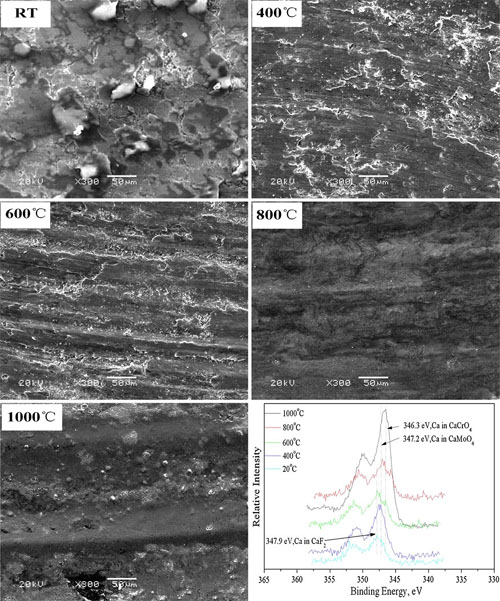

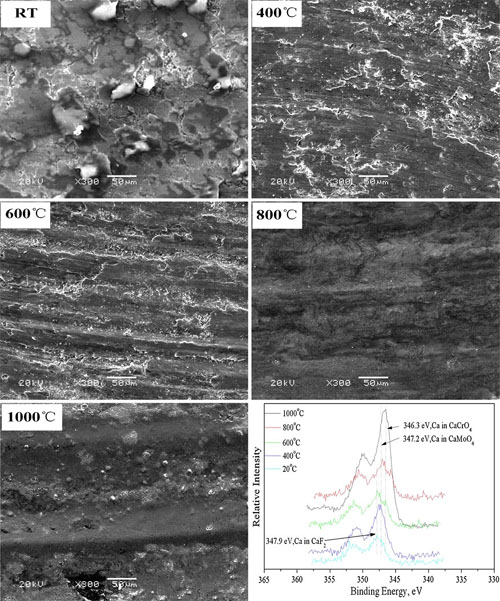

The results showed that the composite had a favorable friction coefficient of about 0.2 and an excellent wear resistance of about 1 9 10-5 mm3N-1m-1 at the high temperatures tested (800 and 1000℃). The excellent self-lubricating performance was attributed to the formation of the glaze film on the worn surface consisting mainly of CaCrO4 and CaMoO4 as high-temperature solid lubricants.

There is an ongoing need for developing high-temperature self-lubricating materials that meet the needs of mechanical systems functioning under severe conditions. NiAl–28Cr–6Mo eutectic alloys are regarded as the most logical choice for high-temperature structural applications because of their relatively high melting point, good thermal conductivity, high elevated temperature creep resistance, and higher fracture toughness. However, the tribological behavior of NiAl matrix self-lubricating composites at higher temperatures has not yet been reported.

The work has received support from the National Natural Science Foundation of China, the Innovation Group Foundation from National Natural Science Foundation, and the National Program on Key Basic Research Project of China.

The findings have been published in Tribol Lett (Tribol Lett (2011) 41:535–540).

Tribol LettPaper

Worn surfaces and XPS results of worn surfaces of NCF after tests at different temperatures