Researchers from the R&D Center of Lubricating and Protecting Materials of the Lanzhou Institute of Chemical Physics of the CAS have in situ synthesized the Ti3Al coating on pure Ti substrate by laser-cladding technology using aluminum powder as the precursor, and investigated the microstructure, microhardness, hightemperature oxidation resistance, and high-temperature wear resistance of the laser-cladding coating.

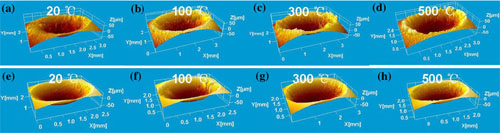

The results show that the Ti3Al coating exhibits better oxidation resistance than pure Ti at elevated temperatures. The Ti3Al coating significantly increases the hardness of the Ti surface. The Ti3Al coating has better sliding wear resistance versus silicon nitride than pure Ti versus silicon nitride under the same reciprocating sliding conditions. The Ti3Al coating produces finer wear debris than Ti under the same sliding conditions.

Titanium and its alloys are extensively used in many industrial applications. However, titanium and its alloys have a high friction coefficient and low hardness, which make their tribological properties very poor and limit their engineering applications.

With the rapid development of industry and engineering technology, titanium and its alloy components usually served in high-temperature environments. However, their high-temperature oxidation/wear resistance is very poor. It would be desirable to improve these high-temperature properties of titanium and its alloys for practical applications such as tribological field, surface engineering area, and the aero-engine industry.

The work has received support from the Ministry of Science and Technology of China and National Natural Science Foundation of China. The detailed report has been published in Tribol Lett (Tribol Lett (2011) 42:151–159).

Tribol LettPaper

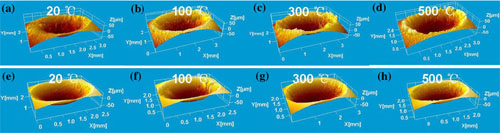

3D non-contact surface mapping of the worn surfaces of the Ti3Al coating and pure Ti substrate at elevated temperature. a–d Pure Ti substrate. e–h Ti3Al coating