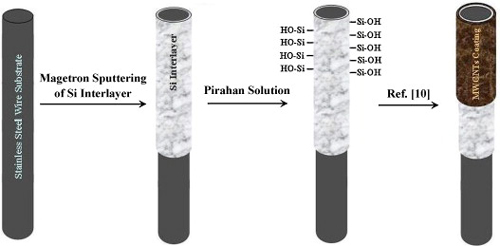

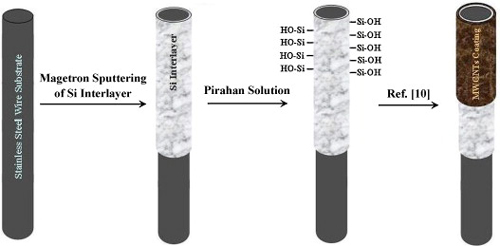

Schematic illustration of the preparation process of the MWCNTs/Si/stainless steel wire fiber.

Researchers from Key Laboratory of Chemistry of Northwestern Plant Resources at Lanzhou Institute of Chemical Physics have adopted magnetron sputtering in fabricating solid phase microextraction (SPME) fiber for the first time.

By forming a Si interlayer through magnetron sputtering, a multiwalled carbon nanotubes (MWCNTs) coating was successfully chemically bonded on the stainless steel wire. The as-prepared MWCNTs/Si/stainless steel wire fiber not only preserved the excellent SPME behavior of MWCNTs/fused-silica fiber, but also overcome its shortcomings of fragileness and hard to handle. As a result, it exhibits many advantages over commercial SPME fibers, including high rigidity, long service life, good stability at high temperature and in acid and alkali solutions, and high SPME effectiveness.

This new surface modification technique might provide a versatile approach to prepare sorbent coatings on unconfined substrates using traditional methods, and represent a key addition to the preparation the family of SPME fibers.

During the last decade, SPME, as a new extraction technology, has gained widespread acceptance for analyte matrix separation and preconcentration due to its high sensitivity, rapidity, simplicity and free of solvents. The core part of SPME technique is to design effective SPME fibers, which usually consist of a substrate fiber and a coating as a stationary phase to adsorb the analytes from samples. At present, most commercial SPME fibers have used fused-silica as substrate.

Fused-silica substrate is very fragile and must be handled with great care, so the service life is very limited. Hence, recent progress in preparation of SPME fibers is being directed at the development of flexible metal-based fibers. However, metal substrates usually have low chemical reactivity and are difficult to adapt to many traditional preparation techniques of SPME fibers. Although some new techniques including chemical corrosion, electrodeposition and anodization have emerged as prospect approaches to prepare sorbent coatings on metal-based fibers, the synthesized coatings are mostly metal-based, and cannot be comparable to many other excellent sorbent coatings. So it is of great importance to develop a versatile approach to combine traditional excellent sorbent coatings and techniques with metal-based fibers.

The work has received support from the National Natural Science Foundation of China. The findings have been published in J. Chromatogr. A( J. Chromatogr. A 1218 (2011) 2835–2840).

J. Chromatogr. APaper