Researchers from Lanzhou Institute of Chemical Physics of the CAS have fabricated the Ni3Al matrix composites with addition of 10, 15, and 20 wt% BaMoO4 and studied the tribological behaviors from room temperature to 800℃.

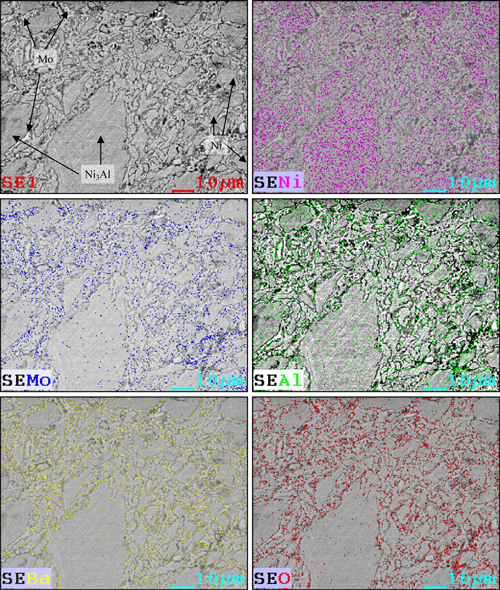

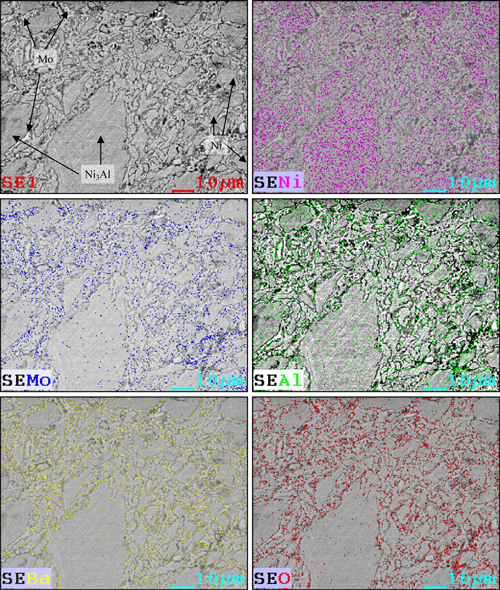

It was found that BaAl2O4 formed during the fabrication process. The Ni3Al composites showed poor tribological property below 400℃, with high friction coefficients (above 0.6) and wear rates (above 10-4 mm3/Nm). However, the composites exhibited excellent self-lubricating and anti-wear properties at higher temperatures, and the composite with addition of 15 wt% BaMoO4 had the lowest wear rate (1.10×10-5 mm3/Nm) and friction coefficient (0.26). In addition, the results also indicated that BaAl2O4 for the Ni3Al composites did not exhibit lubricating property from room temperature to 800℃.

The maintenance of low friction at high temperatures has been very difficult in the past and still are the toughest problems encountered in the field of tribology. Solid lubricants are certainly more appealing for use at high temperature. However, above 500℃, the conventional solid lubricants, such as MoS2 and graphite, can not meet the demand due to their inadequate oxidation resistance in air

Previous study on high-temperature solid lubricant reported that molybdate appeared to be the promising high-temperature solid lubricants. However, till now, the lubricious behavior of BaMoO4 has not been explored in detail. As a high-temperature solid lubricant, and similar to CaWO4 and CaMoO4, BaMoO4 has scheelite structure and adequate thermophysial properties. Therefore, it could be expected as a promising high-temperature solid lubricant.

The work has received support from the National Natural Science Foundation of China (NSFC), the Innovation Group Foundation from NSFC, and the National Program on Key Basic Research Project of China. The findings have been published in Tribol Lett (Tribol Lett (2011) 43:55–63).

Tribol LettPaper

X-ray diffraction (XRD) spectra of the as-produced BaMoO4 powder and the sintered samples: BM10; BM15; and BM20