Researchers from the Lanzhou Institute of Chemical Physics have reported work on the improvement of the tribological performances of diamond-like carbon (DLC) -based solid–liquid synergetic lubricating coatings in high vacuum.

They first homogeneously spun five kinds of liquid lubricants, including MACs, IL, Zdol, PAO and silicon oil on DLC coatings and consequently successfully fabricated the DLC-based solid–liquid lubricating dual-layer coatings. Then they comparatively investigated tribological behaviors of the DLC/steel combinations and steel/steel combinations lubricated with above five liquid lubricants using a high-vacuum tribometer simulated for space environments.

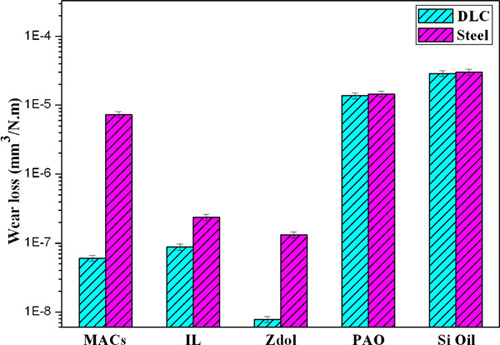

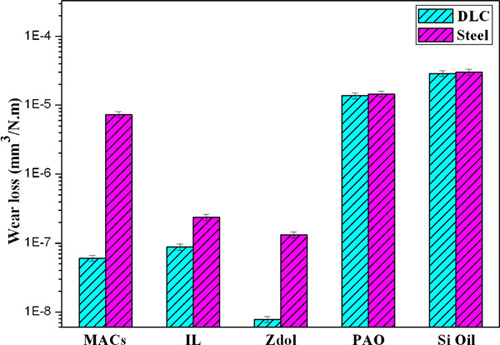

The results showed that the DLC-based solid–liquid coatings of MACs, IL and Zdol have significantly reduced the friction coefficient and improved the wear resistance in high vacuum. The friction coefficients of DLC/steel combinations were nearly reduced in the range of 0.02–0.05 when compared with steel/steel combinations, and the wear rates of DLC/steel combinations were in the range of 1–3 orders of magnitude lower than that of steel/steel combinations. However, PAO and silicon oil exhibited the poorest lubrication performance with high friction coefficient and wear rate. This was attributed to the high viscosities of PAO and silicon oil. The significant improvement in the tribological behavior of solid–liquid lubricating coatings of MACs, IL and Zdol under high vacuum can be attributed to not only the low viscosities and good mobility of these three lubricants, but also the synergy lubrication mechanism by the combination of the solid lubrication effect of the DLC film and the boundary lubrication of the liquid lubricants.

It is expected that this paper could provide additional insight on the development of space tribology and that the principle could be applied to design and construct the surfaces with excellent tribological properties under high vacuum condition and space applications.

The work has received support from the National Program on Key Basic Research Project of China (973 Program) and High Technology Research and Development Program of China.

The findings have been published in Wear (Wear 271 (2011) 889– 898).

WearPaper

Disc wear rates for DLC/steel and steel/steel combination lubricated with different liquid lubricants.