Recently, considerable attention has been paid to the catalytic carbon dioxide reforming of methane (CRM) in view of the environmental protection as well as potential industrial application aspects. Compared with steam reforming or partial oxidation of methane, carbon dioxide reforming of methane provides synthesis gas with a relative low H2/CO ratio, which is more desirable for the direct use as feedstock for the synthesis of oxygenates, hydroformylation, oxo synthesis, and so on.

Whereas, the major drawback of this catalytic process up to now remains the rapid deactivation of the catalysts originating from the sintering of the metal active sites as well as the carbon deposition. Therefore, the recent research focus and nodus in this field have been mainly concentrated on developing catalysts with favorable capacity of anti-coke and anti-sintering.

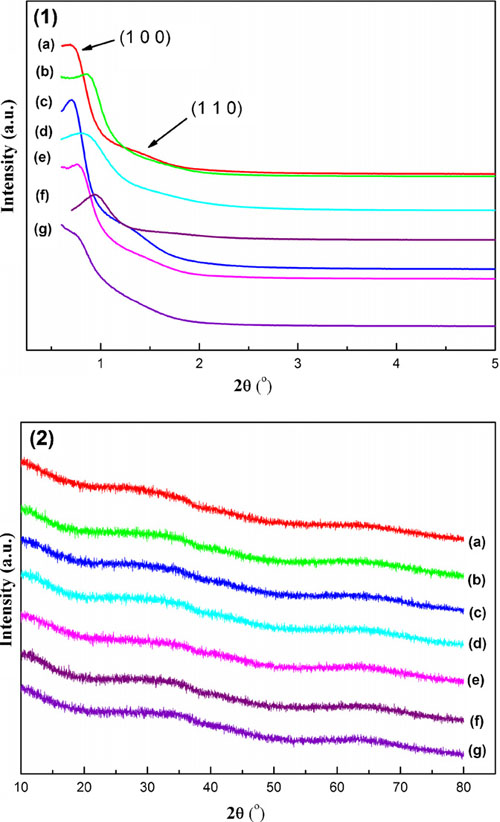

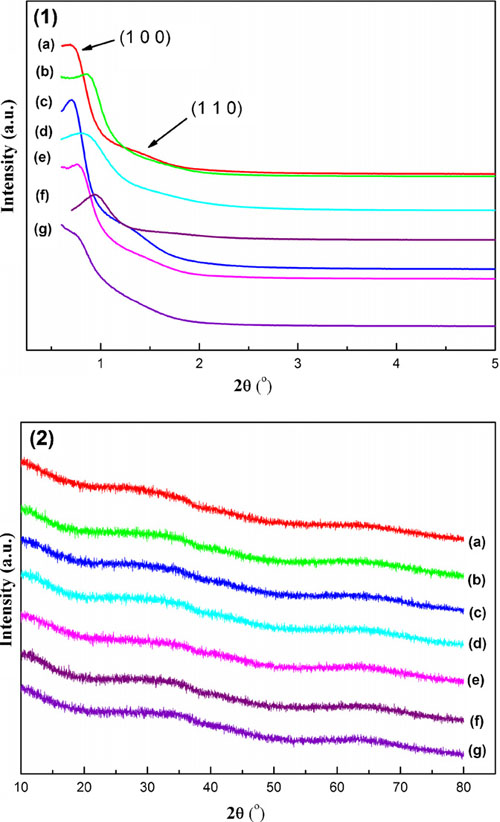

Researchers from the State Key Laboratory for Oxo Synthesis and Selective Oxidation of the Lanzhou Institute of Chemical Physics have prepared ordered mesoporous NiO–MgO–Al2O3 composite oxides with various Ni and Mg contents via one pot evaporation-induced self-assembly strategy. The obtained materials possessed large specific surface areas, big pore volumes, uniform pore sizes, and favorable thermal stability.

It was found that the catalytic performances of the materials for CRM reaction were excellent, displaying high catalytic activity and long catalytic stability.

The ordered mesoporous framework of the M-xNiyMg(100-x-y)Al catalysts played a significant role to endow these merits for these catalysts, which could provide more “accessible” Ni active centers for the reactants and stabilized Ni nanoparticles by the “confinement effect” during the reaction. The effect of the modified Mg on the catalytic performances was also examined. It was found that only moderate addition of the Mg modifier could effectively promote the catalytic properties of the catalysts. Strong metal–support interaction between Ni atom and the mesoporous framework had been formed for all the materials with diverse Ni and Mg containing. The M-15Ni2Mg83Al catalyst exhibited intensive capacity of anti-coking due to the nano-sized Ni particles, which contributed to suppressing coke due to the “size effect”. Although certain amount of coke formed on the surface of M-15Ni2Mg83Al catalyst, the activity did not decrease after 100 h lifetime test, suggesting that proportion of the carbon deposition was active in the reforming reaction.

Because of these favorable properties, ordered mesoporous NiO–MgO–Al2O3 composite oxides could be considered as promising catalysts for CRM reaction.

The work has received support from the National Basic Research Program of China. The findings have been published in Applied Catalysis B: Environmental (Applied Catalysis B: Environmental 108– 109 (2011) 177– 190).

Applied Catalysis B: EnvironmentalPaper