A Ni-based high-temperature self-lubricating composite known as PM 304 has been developed that shows good tribological behavior over a wide range of temperatures (room temperature to 650℃); however, above 800℃, declines in its mechanical properties reduce its wear resistance. Ceramic matrix self-lubricating composites based on Cr3C2, Al2O3, Si3N4, and ZrO2–Y2O3 also exhibit excellent friction and wear behavior within 800℃ and may achieve higher application temperatures, but their inherent brittleness restricts the manufacture of complex shapes and the reliability of applications. However, intermetallic materials possess excellent high-temperature combination properties and may, therefore, be a superior matrix for high temperature self-lubricating composites.

Ni3Al matrix composite with Lubricious tungstate show favorable tribological properties at high emperatures, according to a study by researchers from the State Key Laboratory of Solid Lubrication of Lanzhou Institute of Chemical Physics.

They have fabricated Ni3Al–Ag–BaF2/CaF2–W composites by powder metallurgy route. Over a wide temperature range, the Ni3Al matrix composite with 15 wt% BaF2/CaF2 exhibited favorable tribological properties. Its friction coefficient was in the range of 0.3–0.4, and its wear rate was 0.2–6.2 x10-4 mm3 N-1 m-1.

The low friction coefficient over a broad temperature range between room temperature and 800℃ can be attributed to the synergistic effect of Ag, BaF2/CaF2, BaWO4 and CaWO4.

At a high temperature of 800℃, the glaze layer mainly consisting of BaWO4 and CaWO4 played a significant role in the improvement of tribological behavior. Moreover, the formation of BaCO3 led to high friction coefficient and wear rate at 600℃.

The work has received support from the National Natural Science Foundation of China and National Program on Key Basic Research Project of China (973 Program).

The findings have been published in Tribol Lett (Tribol Lett (2012) 45:251–255).

Tribol LettPaper

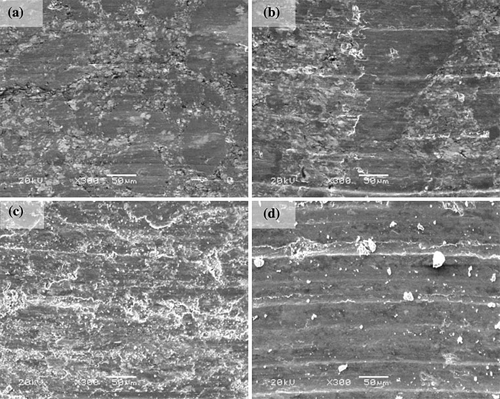

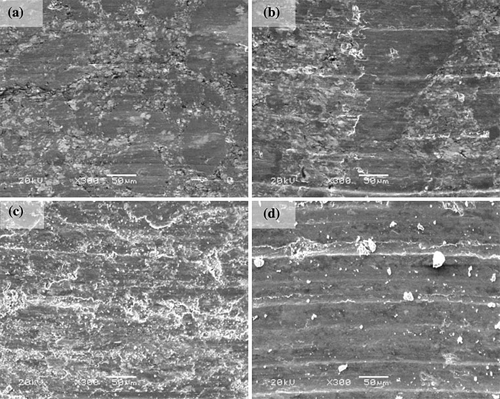

Worn surfaces of WF15 after tests at different temperatures: a room temperature, b 400℃, c 600℃, d 800℃.