Polytetrafluoroethylene (PTFE) blends, a blend of PTFE with other polymers, is a novel material with high mechanical strength and excellent wear resistance, as a result of the good combination between polymer fillers and PTFE matrix and no damage to the counterface. Regrettably, compared with a large number of reports on the tribological behaviors of polymer/inorganic filler composites, the reports on the tribological behaviors of blends are few.

Researchers at the State Key Laboratory of Slid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), have prepared four polytetrafluoroethylene-based polymer blends (PTFE blends) with polyimide (PI), polyether ether ketone (PEEK), poly(phenyl p-hydroxybenzoate) (PHBA), and perfluoroethylene propylene copolymer (FEP) and investigated their tribological properties under aqueous environment.

|

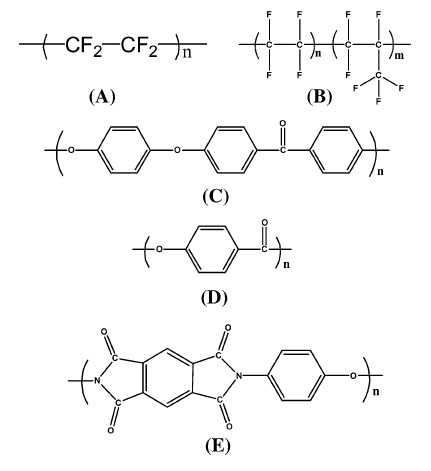

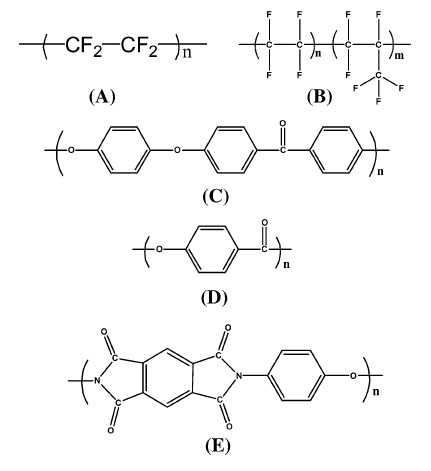

| The structure formula of polymer: (A) PTFE; (B) FEP; (C) PEEK; (D) PHBA; (E) PI |

The results show that by blending PTFE with PI, PHBA, PEEK, and FEP, the microstructure of PTFE is changed, and the wear resistance of PTFE is improved. The blends of PI/PTFE, PHBA/PTFE, and PEEK/ PTFE have much better wear resistance than FEP/PTFE blend. This is because compared with FEP, rigid polymers PI, PHBA, and PEEK can not only improve the load-carrying capacity of PTFE greatly, but also can efficiently prevent the crystalline bands of PTFE being pulled out. The friction coefficients and wear rates of PTFE and its blends under the lubrication of sea water are lower than that under the lubrication of pure water, which ascribes to more excellent lubricating effect of sea water than pure water.

The work has received support from the National Nature Science Foundation of Chinaand the National High-Tech Research and Development Program of China. The findings have been published in Tribol Lett (Tribol Lett (2012) 45:387–395).

Tribol LettPaper