Fe–Ni alloys are typical materials with martensite and austenite structures. Most of the researches focus mainly on their crystal-lography and magnetic properties, but less systematic study has been made on their wear property.

Researchers at State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), have systematically investigated the tribological performance of Fe100-x–Nix (x=20,23,25,30) alloys with various martensite fractions.

|

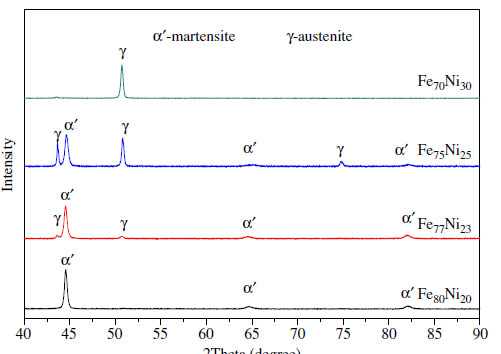

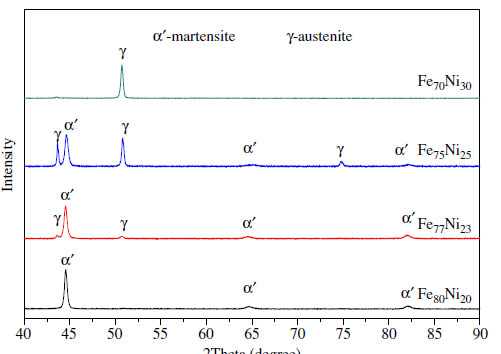

| The XRD patterns of the Fe–Ni alloys. |

The results show that for all the alloys, the friction coefficient decreased with increasing applied load and increased with increasing sliding speed, but there was nearly no difference between the different alloys. The wear rate of the alloys increased with increasing applied load and decreased slightly with increasing sliding speed. Microstructures had great influence on the wear behavior of these alloys. The Fe77Ni23 alloy with well-proportioned martensite exhibited the best wear resistance.

The work has received support from the National Natural Science Foundation of China. The findings have been published in Tribology International(Tribology International51(2012)11–17).