TiAl intermetallics have received considerable interest because of their low density, high strength-to-density ratio, high strength at elevated temperature and good corrosion and oxidation resistance. However, the studies on the tribological properties of titanium aluminides have not received much attention, which will be very important to understand the useful life and reliability of TiAl intermetallics as related friction parts.

Researchers at State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), have investigated the tribological behavior of a Ti-46Al-2Cr-2Nb alloy prepared by hot-pressed sintering under liquid paraffine lubrication against AISI 52100 steel ball in ambient environment and at varying loads and sliding speeds. For comparison, the tribological behavior of a common Ti-6Al-4V alloy was also examined under the same testing conditions.

|

|

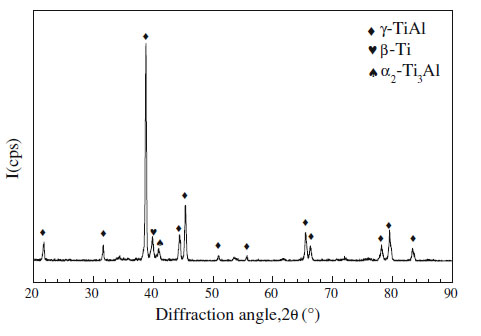

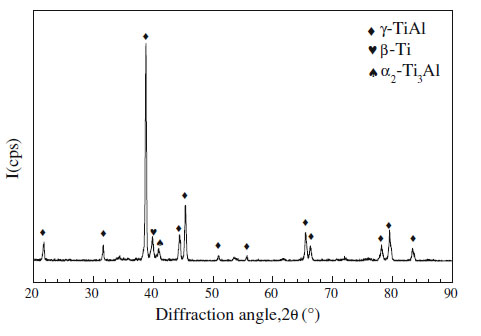

XRD pattern of the Ti-46Al-2Cr-2Nb alloy |

It is found that The friction coefficient of the Ti-46Al-2Cr-2Nb alloy in the range of 0.13–0.18 was significantly lower than that of the Ti-6Al-4V alloy (0.4–0.5), but comparable to that under dry sliding, which indicated that TiAl intermetallics could be more effectively lubricated by liquid paraffine than titanium alloys. Applied load and sliding speed have little effect on the friction coefficient of the Ti-46Al-2Cr-2Nb alloy. The wear rate of the Ti-46Al-2Cr-2Nb alloy was about 45–120 times lower than that of Ti-6Al-4V alloy owing to Ti-6Al-4V alloy could not be lubricated effectively. The wear rate of the Ti-46Al-2Cr-2Nb alloy increased with increasing applied load, but decreased slightly at first and then increased with increasing sliding speed. The wear mechanism of the Ti-46Al-2Cr-2Nb intermetallics under liquid paraffine lubrication was dominated by main plowing and slight flaking-off, but that of the Ti-6Al-4V alloy was plastic deformation and severe delamination.

The work has received support from the National Natural Science Foundation of China and the National 973 Project of China.

The findings have been published in Tribol Lett(Tribol Lett(2012) 46:233–241).