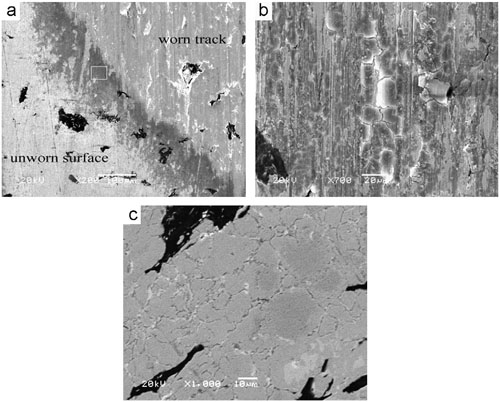

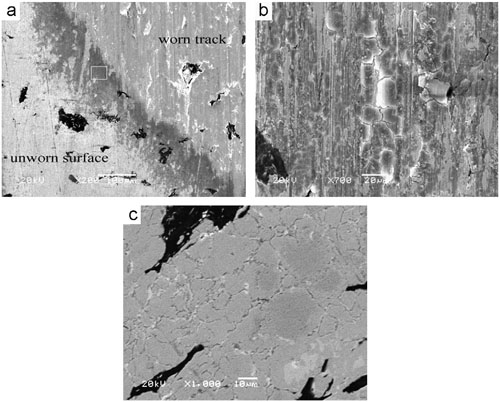

SEM micrographs:(a )corrosion products on the external edge of the worn track, (b) some corrosion products appear in some region of the worn track and (c) morphology of the unworn surfaces of the specimen.

Copper matrix composites containing graphite, lead, silver, etc. show good tribological properties under different sliding conditions. Due to the satisfied anti-friction property, this kind of materials has been extensively used as sliding bearings. However, these materials also show some distinct shortcomings such as low tensile and creep strength as well as low hardness, resulting in failure in many cases. The tribological properties of copper–graphite composites were investigated in recent years. However, the systemic tribological properties of copper matrix composites have not been done under sea water condition.

Researchers at State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), have fabricated bronze–graphite composites containing 8.415wt% of Ni-coated graphite by P/M method and found that the addition of nickel coated graphite increases mechanical and tribological properties of bronze–graphite composites.

The friction coefficient of composites decreased with increasing graphite content. The wear resistance was improved by the addition of Ni-coated graphite but degraded at high graphite content. The results indicated that bronze–nickel coated graphite composites showed much better tribological properties in comparison with bronze and bronze uncoated graphite composites. The composite with 11.7wt% nickel coated graphite showed the best tribological properties. The addition of nickel coated graphite not only increased the mechanical properties, but improved tribological properties.

The work has received support from the National Natural Science Foundation of China and National Program on Key Basic Research Project of China (973 Program). The findings have been published in Tribology International(Tribology International53 (2012) 76–86).