Abstract:

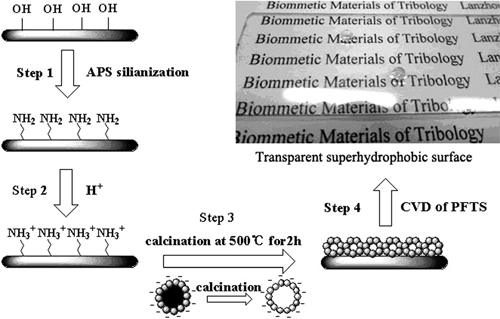

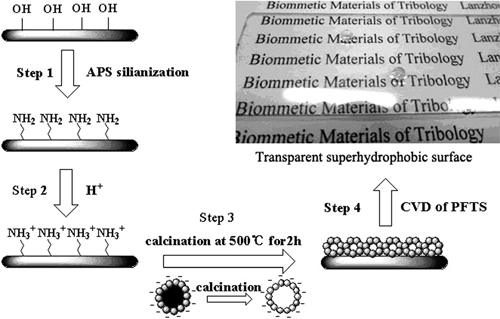

The high transparent superhydrophobic surface covered with hollow spheres has been fabricated through a carbon template route. The as-prepared coating without treating with low surface energy materials showed super

|

| Schematic illustration of the procedure to prepare transparent superhydrophobic surface. |

hdrophilic and anti-fogging properties while displayed superhydrophobic characteristics after surface modification. Furthermore, such superhydrophilic/superhydrophobic glasses both exhibited a relatively high transmittance, and it is also demonstrated that the thickness of coating affects the transmittance and wettability from a control experiment. For comparison, we studied the anti-fogging properties of the transparent superhydrophobic, superhydrophilic, and the ordinary glass, showing absolutely different fogging characteristics.

Conclusion:

In summary, we presented a facile route to fabricate highly transparent superhydrophobic coating based on silica capsule particles. The resultant superhydrophobic coatings show a static contact angle of 152° and a sliding angle less than 8°. By adjusting the cycles of dip-coating, different transmittance and water contact angle can be measured. Finally, we also discussed the anti-fogging characteristics of such a coating before and after modification of low surface energy materials. The results demonstrate that the good wettability was suitable for anti-fog. More importantly, through the observations of the formation and vanishing of the fog on superhydrophobic glass, the results reveal that the evaporation rate of the fog on superhydrophobic surfaces can be tremendously improved, which can envisage their potential to a wide range of applications such as selfcleaning windshield, antifogging and antireflection optical devices, ultra-fast spreading for bio-molecules analysis, solar cells panels, and so on.

Published in Appl. Phys. Lett.101, 033701 (2012)