Abstract: Due to strongly tribological atmosphere sensitivity of carbon-based coatings, it is of extreme significance to investigate their friction and wear behaviors in different atmospheres. In this letter, duplex nc-TiC/a-C(Al) nanocomposite carbon-based coating coupled with high hardness, low internal stress and high adhesion strength was successfully fabricated using magnetron sputtering process. The friction and wear behaviors of as-fabricated coating were evaluated in dry N2, humid N2, air, dry O2, and humid O2 atmospheres, respectively. Results show that the asfabricated coating possesses very high friction and wear due to the strong covalent bond interactions at the sliding interface caused by the free  -bonds on the coating surface in dry N2 atmosphere. Whereas the free

-bonds on the coating surface in dry N2 atmosphere. Whereas the free  -bonds can be efficiently terminated and passivated by water and/or oxygen molecules to weaken the strong covalent bond interactions to result in low friction and wear of coating in humid N2, air, dry O2, and humid O2 atmospheres. The compact and homogeneous carbonaceous tribo-layer on the counterpart is mainly responsible for the lowest friction and wear of coating in humid N2 atmosphere. Whereas the tribo-layer can be restrained to a certain extent by the tribochemical reaction, especially it results in a nearly negligible carbonaceous tribo-layer on the counterpart in dry O2 atmosphere, which is mainly responsible for largely increased friction and wear of coating.

-bonds can be efficiently terminated and passivated by water and/or oxygen molecules to weaken the strong covalent bond interactions to result in low friction and wear of coating in humid N2, air, dry O2, and humid O2 atmospheres. The compact and homogeneous carbonaceous tribo-layer on the counterpart is mainly responsible for the lowest friction and wear of coating in humid N2 atmosphere. Whereas the tribo-layer can be restrained to a certain extent by the tribochemical reaction, especially it results in a nearly negligible carbonaceous tribo-layer on the counterpart in dry O2 atmosphere, which is mainly responsible for largely increased friction and wear of coating.

Conclusion

|

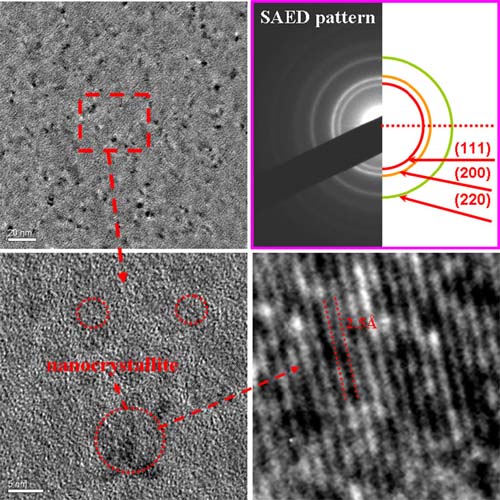

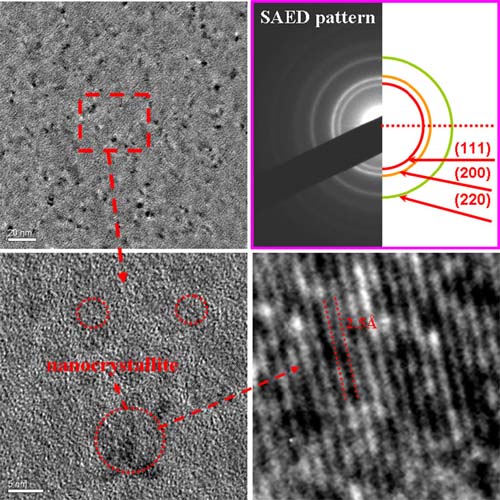

| HRTEM bright-field images and SAED pattern of nc-TiC/a-C(Al) nanocomposite carbon-based coating |

The following conclusions can be drawn from the current study:

1. The as-fabricated nc-TiC/a-C(Al) carbon-based coating exhibits typical nanocrystallite/amorphous microstructure and good combined mechanical properties.

2. In dry N2 atmosphere, nc-TiC/a-C(Al) coating present very high friction and wear due to the strong covalent bond interactions at the sliding interface caused by the free -bonds on the coating surface.

-bonds on the coating surface.

3. The free  -bonds of surface carbon atoms are efficiently terminated and passivated by water and/or oxygen molecules to weaken the strong covalent bond interactions, resulting in a reduced friction, and wear of nc-TiC/a-C(Al) coating in the humid N2, air, dry O2, and humid O2 atmospheres.

-bonds of surface carbon atoms are efficiently terminated and passivated by water and/or oxygen molecules to weaken the strong covalent bond interactions, resulting in a reduced friction, and wear of nc-TiC/a-C(Al) coating in the humid N2, air, dry O2, and humid O2 atmospheres.

4. The compact and homogeneous tribo-layer formed on the counterpart is mainly responsible for the lowest friction and wear of nc-TiC/a-C(Al) coating in humid N2 atmosphere.

5. The tribo-layers can be restrained to a certain extent by tribo-chemical reaction among the coating, steel ball, and oxygen molecules; especially, it results in nearly negligible carbonaceous tribo-layer on the counterpart in dry O2 atmosphere, which is mainly responsible for largely increased friction and wear of coating similar to that in dry N2 atmosphere.

Published in Tribol Lett(2012) 47:435–446

-bonds on the coating surface in dry N2 atmosphere. Whereas the free

-bonds on the coating surface in dry N2 atmosphere. Whereas the free  -bonds can be efficiently terminated and passivated by water and/or oxygen molecules to weaken the strong covalent bond interactions to result in low friction and wear of coating in humid N2, air, dry O2, and humid O2 atmospheres. The compact and homogeneous carbonaceous tribo-layer on the counterpart is mainly responsible for the lowest friction and wear of coating in humid N2 atmosphere. Whereas the tribo-layer can be restrained to a certain extent by the tribochemical reaction, especially it results in a nearly negligible carbonaceous tribo-layer on the counterpart in dry O2 atmosphere, which is mainly responsible for largely increased friction and wear of coating.

-bonds can be efficiently terminated and passivated by water and/or oxygen molecules to weaken the strong covalent bond interactions to result in low friction and wear of coating in humid N2, air, dry O2, and humid O2 atmospheres. The compact and homogeneous carbonaceous tribo-layer on the counterpart is mainly responsible for the lowest friction and wear of coating in humid N2 atmosphere. Whereas the tribo-layer can be restrained to a certain extent by the tribochemical reaction, especially it results in a nearly negligible carbonaceous tribo-layer on the counterpart in dry O2 atmosphere, which is mainly responsible for largely increased friction and wear of coating.

-bonds on the coating surface.

-bonds on the coating surface. -bonds of surface carbon atoms are efficiently terminated and passivated by water and/or oxygen molecules to weaken the strong covalent bond interactions, resulting in a reduced friction, and wear of nc-TiC/a-C(Al) coating in the humid N2, air, dry O2, and humid O2 atmospheres.

-bonds of surface carbon atoms are efficiently terminated and passivated by water and/or oxygen molecules to weaken the strong covalent bond interactions, resulting in a reduced friction, and wear of nc-TiC/a-C(Al) coating in the humid N2, air, dry O2, and humid O2 atmospheres.