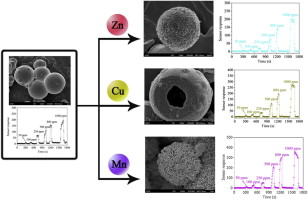

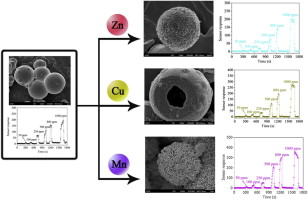

Abstract: In this work, non-doped SnO2 samples, and SnO2 samples doped with Zn(II), Cu(II), or Mn(II), having hierarchical microstructures, were prepared using an otherwise identical hydrothermal process, followed by annealing. The morphological and structural characteristics of the samples were systematically characterized by X-ray powder diffraction (XRD), field emission scanning electron microscopy (FESEM), transmission electron microscopy (TEM), Brunauer-Emmett-Teller (BET) measurements, and X-ray photoelectron spectroscopy (XPS). Ten gas sensors were constructed from each material, and compared as to detection of gas-phase ethanol, acetone, glacial acetic acid, methanol, and ammonia. The results indicated, for example, that Sn02 containing 2.91% Mn dopant exhibited a 2.5-fold higher gas detection response toward ethanol at 100 ppm than that of the non-doped material. The fastest response time for 100 ppm ethanol was found for Cu(l1)-doped SnO2 (9.7 s), compared with 12.4 s for non-doped 5n02. Graphs of sensor response versus operating temperature for SnO2 containing different types and quantities of dopant exhibited quite different morphologies. The gas-sensing mechanism appears to involve reactions between the detected gases and the various oxygenous ions, such as O, O-2(-). and O2-, present at the surface of the sensor. (C) 2015 Elsevier Inc. All rights reserved. Key Words: Hierarchical SnO2; Zn (Cu/Mn) doping; Gas sensing properties; Sensing mechanism

Published in JOURNAL OF COLLOID AND INTERFACE SCIENCE, 448 265-274; 10.1016/j.jcis.2015.02.045 JUN 15 2015

|