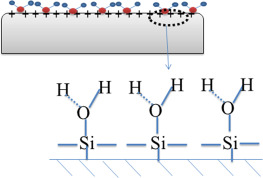

Abstract: Spray-dried mullite powder was plasma sprayed onto steel substrates to form mullite coating. The microstructure of mullite coating and its tribological properties coupled with Si3N4 ball under dry sliding as well as water and hydrochloric acid solution were investigated. Results indicate that mullite coating exhibits high porosity and retains an amorphous phase. The mullite coating-Si3N4 exhibits greatly reduced coefficient of friction under HCl solution, due to the boundary lubrication of the hydrated silica layer and the hydrodynamic lubrication of the acid solution. Moreover, since the wedging action of water, the mullite coating has the highest specific wear rate under water environment. (C) 2015 Elsevier Ltd. All rights reserved. KeyWords Plus:SILICON-NITRIDE; HYDRODYNAMIC-LUBRICATION; AQUEOUS-SOLUTIONS; BARRIER COATINGS; WATER; MICROSTRUCTURE;TEMPERATURE; CERAMICS; COMPOSITES; MECHANISMS

Published TRIBOLOGY INTERNATIONAL, 91 32-39; 10.1016/j.triboint.2015.06.022 NOV 2015

|