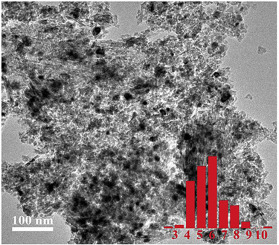

Abstract: In this study, an active Ni-Co/Al2O3 catalyst for steam reforming of ethanol (SRE) was reported. Results indicated that the dispersion of active species can be tuned by preparation methods, i.e., by step-step impregnation method and co-impregnation method separately. By comparing the activities and stabilities in the temperature range of 250-650 degrees C under atmospheric pressure, and correlating the characterization results of H-2 chemisorption, XRD, HRTEM and TGA, we found the catalytic performance were dependent on the surface species dispersion over support which could be modulated by preparation process. The ethanol conversion on Ni-Co/Al2O3, Co/Ni/Al2O3 and Ni/Co/Al2O3 catalysts were 68.7%, 50.9%, 36.6% at 350 degrees C, corresponding to the metal species dispersion data 31.5%, 29.1% and 28.0%, respectively. TEM results confirmed these differences corresponded to the metal particles size of the bimetallic catalysts distribution. Higher dispersed catalyst exhibited higher anti-coking properties and stabilities. Under the optimized conditions, the ethanol conversion, H-2 and CO2 selectivities were 97.2%, 88.9% and 87.4%, respectively during a 100 h reaction over Ni-Co/Al2O3 catalyst at 550 degrees C, LHSV of 7.5 h(-1) and a C2H5OH/H2O molar ratio of 13. KeyWords Plus: SUPPORTED METAL-CATALYSTS; NICKEL-COBALT CATALYSTS; ACETIC-ACID; BIO-ETHANOL; NI/CEO2-ZRO2 CATALYST; NI/AL2O3 CATALYSTS; PARTIAL OXIDATION; CARBON-MONOXIDE; LOW-TEMPERATURE; H-2 PRODUCTION Published in INTERNATIONAL JOURNAL OF HYDROGEN ENERGY, 41 (5):3349-3362; 10.1016/j.ijhydene.2015.09.063 FEB 9 2016

|