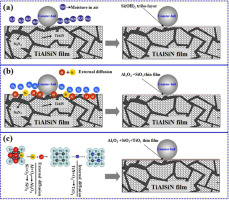

Abstract: TiAlSiN coatings were produced with different Al and Si contents by hybrid PVD technology. The tribological properties of TiAlSiN coatings from room temperature to 800 degrees C were evaluated. The friction and wear of TiAlSiN coatings show strong dependence on stoichiometry and test temperature. The formation of SiO2 center dot nH(2)O tribo-layer contributes to the decrease of the wear rate and friction coefficient at room temperature. Al2O3 and SiO2 produced at 600 degrees C can reduce the wear rates of TiAlSiN coatings. Moreover, the rutile TiO2 phase produced at 800 degrees C plays the role of lubrication in the process of sliding. KeyWords Plus: AL-SI-N; XPS ANALYSIS; NANOCOMPOSITE COATINGS; MECHANICAL-PROPERTIES; OXIDATION RESISTANCE; FILMS; TI; MICROSTRUCTURE; DEPOSITION; SYSTEM Published in TRIBOLOGY INTERNATIONAL, 98 133-143; 10.1016/j.triboint.2016.02.034 JUN 2016

|