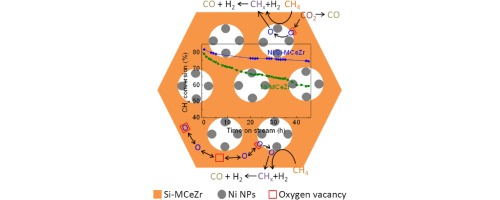

Abstract: A series of mesoporous silica-ceria-zirconia composite (Si-MCeZr) with variable Si/(Ce + Zr) molar ratios are prepared by improved evaporation induced self-assemble strategy (EISA). TEM and XRD measurements show that the Si-MCeZr frameworks are made of ceria-zirconia solid solutions crystalline nanoparticles and the amorphous silica that serves as glue connecting the nanocrystals. The further heating treatment (700 degrees C) reveals that the thermal stability of Si-MCeZr is higher than that of Si free mesoporous ceria-zirconia solid solution (MCeZr). This might be due to the key role of the introduction of Si, which improves the thermal stability via inhibiting the growth of nanoparticles and crystallization of ceria-zirconia solid solution nanoparticles. Furthermore, the Si-MCeZr materials are applied as support to prepare nickel based catalysts (Ni/Si-MCeZr) for CO2 reforming of CH4. The XPS analyses show that the concentration of surface oxygen vacancies in Ni/Si-MCeZr increases with the increasing of Si/(Ce + Zr) molar ratios. The long term reforming test demonstrates that the catalytic stability of Ni/Si-MCeZr is improved compared to Si free nickel based catalyst (Ni/MCeZr). The obtained results indicate that enhanced durability may originate from the higher concentration of oxygen vacancies, more rapid oxygen mobility and improved nickel dispersion in Ni/Si-MCeZr, which contribute largely to higher catalytic activity and decoking ability in reforming reaction, as confirmed by TG-DSC and XRD characterizations of catalysts before and after stability tests. (C) 2016 Elsevier B.V. KeyWords Plus: SOLID-SOLUTION CATALYSTS; OXYGEN STORAGE CAPACITY; SYNTHESIS GAS; ACTIVITY BEHAVIORS; SUPPORTED RHODIUM; REDOX BEHAVIOR; RU CATALYSTS; MIXED OXIDES; CO2; PERFORMANCE Published in APPLIED CATALYSIS A-GENERAL, 520 140-150; 10.1016/j.apcata.2016.04.020 JUN 25 2016

|