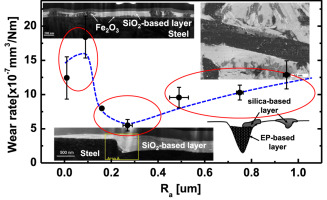

Abstract: The topographic effect of steel counterface, finished by mechanical grinding with R-a ranging from 0.01 to 0.95 mu m, on the structure and functionality of the tribofilm of a hybrid nanocomposite, i.e. epoxy matrix filled with monodisperse silica nanoparticles, carbon fibers and graphite, was systematically investigated using a pin-on-disc sliding contact geometry. The nanostructure of the tribofilm was comprehensively characterized by using combined focused ion beam and transmission electron microscope analyses. It was identified that oxidation of the steel surface, release, compaction and tribosintering of silica nano particles and deposition of an epoxy-like degradation product as well as fragmentation of carbon fibers are main mechanisms determining the structure and functionality of the tribofilm. The size of roughness grooves determines the type and size class of wear particles, to be trapped at the surface. An optimum groove size leading to a maximum of surface coverage with a nanostructured tribofilm formed mainly from released silica nanoparticles was identified. KeyWords Plus: RUBBING STEEL SURFACES; TRIBOLOGICAL PROPERTIES; COUNTERFACE TOPOGRAPHY; HYBRID NANOCOMPOSITES; OXIDE PARTICLES; CARBON-FIBERS; MILD WEAR; COMPOSITES; FRICTION; BEHAVIOR Published in WEAR, 364 48-56; 10.1016/j.wear.2016.06.012 OCT 15 2016

|