Researchers of the R&D Center of Lubricating and Protecting Materials of the Lanzhou Institute of Chemical Physics (LICP), CAS, have successfully prepared a carbon film on SiC using CCl4 as a reactant.

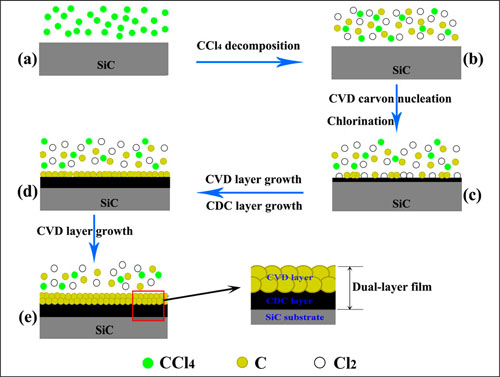

A dual-layer carbon film on SiC is synthesized using a combination of carbide derived carbon (CDC) process and chemical vapor deposition (CVD) in a CCl4– containing atmosphere. The film is composed of a CDC sub-layer formed by chlorination of the SiC and a CVD top-layer by pyrolyzing CCl4. The temperature plays an important role in the film formation. Since the chlorination rate is greatly superior to CVD process, the CDC layer is much thicker in comparison with CVD layer. The thickness of CDC layer can be reduced by H2 introduction and evaporating the CCl4 at lower temperature. The formation mechanism of the dual-layer film is proposed as two simultaneous and competitive processes, namely, the chlorination of SiC and the growth of CVD layer.

The prepared dual-layer carbon film is expected to be a better interfacial coating than CDC in metal-matrix composite, and a good lubricating coating in mechanical seal.

In recent years, CDC materials have attracted considerable interest due to their high specific surface area and controlled pore size distribution, which make them perform well in areas such as hydrogen storage, catalysts, battery or supercapacitor electrodes, etc. The CDC materials reported previously were commonly prepared by high-temperature chlorination of carbides. However, the removal of metallic atoms in CDC process results in the formation of a collapsed noncrystalline carbon with up to 80% pore volume. Besides chlorine, halogenated hydrocarbons, such as CCl4 and CHCl3, are proposed to be used for preparing free carbon on carbides in early 1997. However, up to now, such attempt is rarely reported.

The detailed report of the work was published in CARBON (CARBON (2011) 732-736).

The schematic picture of formation mechanism for the dual-layer carbon film.(Image by LU Jinjun et al.)