The review on TiO2 nanotubes(NTs) authored by the surface/interface research group at the State Key Laboratory of Solid Lubrication of the Lanzhou Institute of Chemical Physics of the CAS has been published in the latest issue of Journal of Materials Chemistry. It is highlighted by the journal and is one of the top ten most-read articles from the online version of the journal for May 2011.

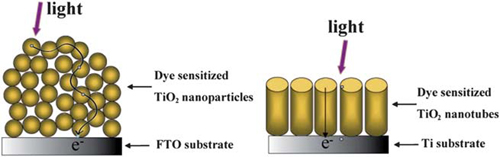

This review starts with a brief introduction to TiO2 nanotubes, and then discusses in more detail how to optimize the structure of TiO2 NTs for the fabrication of highly efficient solar cells, including the controllable fabrication of perfectly aligned TiO2 NTs, optimization of the tube parameters, strategies of sensitization, improvement of the interface adhesion in polymer/TiO2 solar cells and how to make devices flexible. Some key challenges and perspectives for future research are also tentatively discussed.

Looking for alternative resources is currently a hot research topic worldwide in academic society. Among all potential technologies, photovoltaic solar cells have been highly valued, new photoelectric conversion materials and device configurations are continuously invented and world-record efficiencies are broken time and time again. Besides silicon, anatase TiO2 is another core inorganic material that is also capable of efficiently harvesting light and is considered the prominent cathode electrode material in solar cells. Among different shapes of titania, TiO2 nanotubes have raised a lot of interest in the last decade.

The research interests of the surface/interface group focus on the fabrication of TiO2 nanotubes, structure optimization of TiO2 nanotubes approaches for solar cells, etc. They have achieved a series of advances.

Firstly, perfectly aligned top porous TiO2 nanotubes array has been successfully prepared and the controllable growth of TiO2 nanotubes has also been realized. The controllable range of tube diameter is 20-250 nm and tube length is 150 nm-500 μm. The materials have showed excellent properties in photocatalysis, dye-sensitized solar cells and super-hydrophobic areas. Based on these, researchers have developed a facile approach to prepare flexible TiO2 nanotubes/conducting polymer (semiconductors, metals) nanowire and nanotube coaxial materials with large areas via electrochemical deposition in top-porous TiO2 NTs. It is the first time to successfully deposit conducting polymer nanowires and nanotubes into TiO2 NTs to form well-positioned phases. The nanohybrids are found for the first time to be highly flexible after peeling off from mother substrates, which is very interesting to fabricate flexible solar cells.

As for the improvement of interface adhesion, researchers have demonstrated a new biomimetic anchor of N-(3, 4-dihydroxyphenethyl)-pyrrole-2-carboxamide (Dop-Py) for electrochemical polymerization polypyrrole (PPy) inside nanoporous TiO2 NTs to form coaxial heterojunction materials. The biomimetic anchor layer grafting to TiO2 surface can speed up the polymerization rate and most importantly strengthen the interface adhesion between the PPy and TiO2. After binding the Dop-Py layer, the TiO2/Dop-Py/PPy composite film indicates a smaller charge transfer resistance and film resistance which offers faster electron transport of redox species to the substrate surface and suggests a new, effective and promising strategy for fabrication of ordered heterojunction composite materials. The resistance of nanohybrid composite materials with interlaced structures shows good reversibility with or without illumination. These findings have been published in Adv. Mater. (2009, 21, 1964–1967), Chem. Mater. ( 2009, 21 ,1198–1206), Adv. Funct. Mater. (2009, 19, 1930–1938), ACS Nano (2009, 3, 1249–1257) and J. Mater. Chem. ( 2010, 20, 6910–6915).

The work has received support from National Natural Science Foundation of China and National Program on Key Basic Research Project of China (973 Program).

A comparison of the electron pathways through nanoparticle and nanotubular structured TiO2(Image by ZHOU Feng et al.)

Surface morphology of tubular, porous and micro-patterned TiO2 nanotubes and the fabrication process of chemically bonded p–n heterojunctions (Image by ZHOU Feng et al.)