Polymer brushes have been widely used in surface modification, nano polymer materials, etc. Controlled/“living” surface-initiated radical polymerization offers the possibility to generate brushlike polymeric thin films with controllable thickness, composition, and architecture. However, in standard surface-initiated ATRP, a CuI complex is used as the catalyst and high monomer concentrations are required to maximize the polymer growth. Moreover, polymerization solutions often cannot be reused without purification, leading to inefficient use of the monomers. Furthermore, trace amount of oxygen will oxidize CuI to the deactivating CuII species and therefore, brush growth is usually carried out in an inert atmosphere.

|

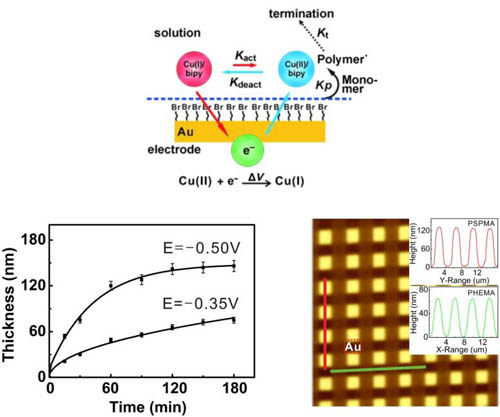

| Mechanism of polymer brush growth using eATRP. (Image by ZHOU Feng et al.) |

The surface/interface research group at the State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), has accomplished the controlled growth of polymer brushes under ambient conditions using surface-confined electrochemically atom-transfer radical polymerization (eATRP) and the multiple reuse of the polymerization solution.

The thickness of polymer brushes is controlled through adjusting the fraction of initiator and applied potentials. It allows polymer brushes to grow in the presence of ambient air and the monomer solution can be reused for several times, which is very promising for the polymerization of specialty monomers and for the growth of biocompatible, protein-resistant polymer brushes on nonplanar substrates with complex shapes.

The work has been published in Angew. Chem. Int. Ed. (Angew. Chem. Int. Ed. 2012, 51, 5092 –5095) and featured as the “hot paper” of the journal. It has received support from the National Natural Science Foundation of China and CAS.