Researchers at the R&D Center of Lubricating and Protecting Materials of the Lanzhou Institute of Chemical Physics have found that the incorporation of hydroxyl-terminated polydimethylsiloxane (HTPDMS) can significantly improve the friction and wear properties of polyurethane/epoxy resin (PU/EP) interpenetrating polymer network composites (IPN). The friction and wear properties of the HTPDMS-modified PU/EP IPNs depend on the content of the HTPDMS. In addition, HTPDMS with low molecular weight and low viscosity can improve the friction and wear properties of PU/EP IPN more obviously, which had better tribological properties and practical values.

Researchers have obtained the above conclusion through a systematic investigation on the tribological properties of two kinds of HTPDMS-modified castor oil-based PU/EP IPN under dry sliding conditions.

HTPDMS-modified PU/EP IPNs showed good damping, thermal, and mechanical properties, which could be used as structural damping materials. The tribological behaviors of the materials are as important as their damping properties. However, the literature is scarce with regard to the tribological behaviors of PU/EP IPN composites.

The work has received support from the National Science Foundation for Distinguished Young Scholars, Science Fund for Creative Research Groups of the National Natural Science Foundation of China and National Program on Key Basic Research Project of China. The findings have been published in Tribol Lett (Tribol Lett (2011) 43:319–327).

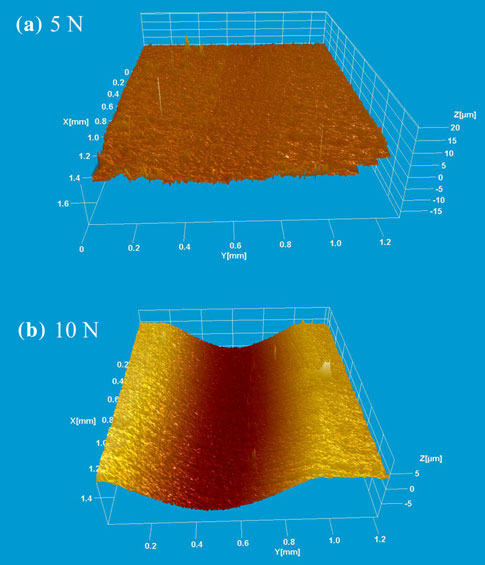

3D noncontact surface mappings of the wear scars of 10% HTPDMS-1000-modified PU/EP IPN: a 5 N, b 10 N (Image by WANG Qihua et al.)

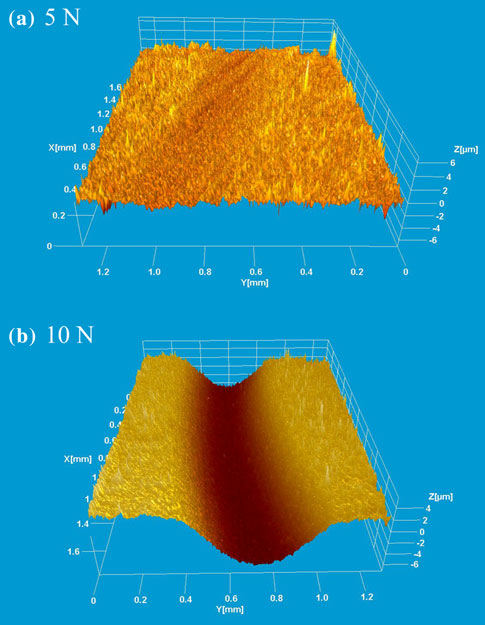

3D noncontact surface mapping of the wear scars of 10% HTPDMS-2800-modified PU/EP IPN: a 5 N, b 10 N (Image by WANG Qihua et al.)