Studies on the triboelectrification electrostatic potential of MC nylon 6 under point dry sliding conducted by Prof. Yang Shengrong of LICP, CAS, was recently published in Tribology Letter (Tribol. Lett. 2009 36:199–208).

In the work, the researchers first designed a piece of equipment for instantaneously monitoring the continuous dynamic variations of triboelectrification electrostatic potential, friction coefficient, and temperature at the tribointerface of insulation materials by themselves. Using the self-designed device, they studied the dynamic variations in the triboelectrification electrostatic potential of MC nylon 6 under ball-on-disk point contact dry sliding and discussed the influence factors on the change of triboelectrification electrostatic potential. Researchers found that an obvious influence on magnitude and change tendency of the triboelectrification electrostatic potential of MC nylon 6 could be produced only when the combined action of load (P) and speed (V) made PV values reach a certain degree. After MC nylon 6 rubbing against the bearing steel, the triboelectrification electrostatic potential of MC nylon 6 was not constant, especially under severe sliding conditions. A positive charge existed on the tribo-surface of MC nylon 6 and a negative charge existed on the tribo-surface of the counterpart steel. During the severe wear process, the experimental conditions, wear rate, the formation of transfer film, and the fraction of film on the counterpart as well as frictional heat were the most significant interaction effects on the abrupt change in the triboelectrification electrostatic potential among all factors studied.

The results provide valuable information in terms of achieving a good breakthrough point for the tribological study of polymer materials and a guidance to the tribological application of these polymer materials.

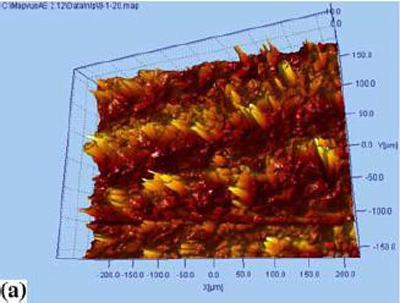

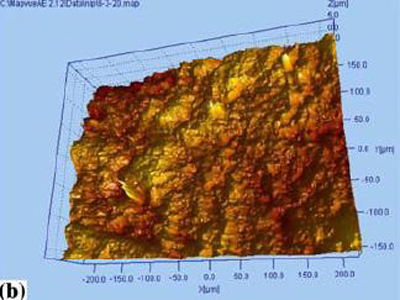

Three-dimensional (3D) surface topographies of MC nylon 6 before and after friction. a Original surface, b worn surface