Diamond-like carbon (DLC) protective coatings with excellent strength and toughness properties, low friction and low environmental sensitivity has always been a challenge in the field of hard solid lubricating coatings.

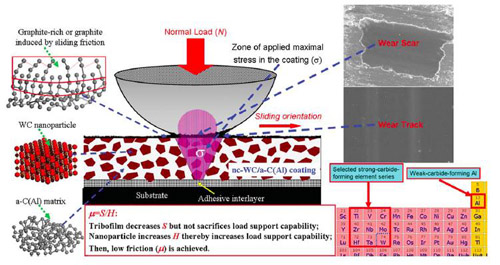

The research group headed by Professor XUE Qunji and Professor WANG Liping at State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), has successfully fabricated low friction multi-doped carbon-based nanocomposite coatings by multiple-target magnetron sputtering deposition technique. A series of carbon-based nanocomposite coatings, including the nc-TiC/a-C(Al), nc-VC/a-C(Al), nc-CrC/a-C(Al), nc-ZrC/a-C(Al), nc-NbC/a-C(Al), nc-MoC/a-C(Al), nc-HfC/a-C(Al) and nc-TaC/a-C(Al) protective coatings have been fabricated. The nanocomposite coatings were designed using First principle and finite element simulation, and fabricated via co-incorporation of strong-carbide-forming (SCF) metal weak-carbide-forming (WCF) Al.

|

| Schematic diagram of frictional mechanism for the nc-WC/a-C(Al) carbon-based coating. (Image by WANG Liping et al.) |

These coatings possess typical nano-crystalline/amorphous structure, excellent strengthening and toughening properties and low environmental sensitivity. Based on Raman spectra, HRTEM analysis of focused ion beam (FIB) technique prepared coatings, thermodynamic calculation of the micro-area of worn surfaces, it has been found that the thickness of the low shear strength graphitic interlayer formed due to friction is 30nm.In particular low friction (~0.05) of these coatings can be acquired by creating a strong thermodynamic driving force to promote phase segregation of graphitic carbon from the a-C structure so as to form a low shear strength graphitic tribo-layer on the friction contact surfaces.

This study proposes a new design for low friction carbon-based nanocomposite coatings by tailoring the microstructure and phase segregation, and thereby it contributes to better controlling the mechanical and tribological properties.

The work has been accomplished by cooperating with National Centre for Advanced Tribology at Southampton (nCATS). It has received support from National High-tech R&D Program of China (863 Program) and National Natural Science Foundation of China. The findings have been published in Journal of Materials Chemistry(2012,22,15782).