Diamond-like carbon (DLC) films have gained ever-growing popularity in scientific and industrial communities due to their combination of high wear-resistance and outstanding friction-reducing ability. More strikingly, highly hydrogenated DLC films show superlow friction coefficient (<0.01) in vacuum and inert environments.

However, due to the insufficient understanding of the friction mechanism of DLC, the friction behavior of DLC can hardly be controlled, which has greatly limited the application of DLC. Various theories concerning the mechanism that dominates the friction behavior of DLC films have been put forward. But there’s still no one that is widely accepted. Thus, to find the key factor influencing the friction behavior of DLC is a challenge in the study of DLC.

Researchers from the Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) have revealed friction behavior of DLC in high vacuum in their recent study, which sheds insight on the application of DLC.

They have explored the friction mechanism of DLC by varying the rotating speed in conjunction with vacuum pressure. Unlike results obtained in ambient air, the friction coefficient in vacuum does not show a consistent decrease with increasing rotating speed. It is found that a higher friction coefficient is accompanied with a higher degree of graphitization of the sliding surface. They claim that the higher degree of graphitization is caused by the higher friction force. Moreover, the friction coefficient is found to depend on the ratio of ambient pressure to rotating speed, which suggests that the passivation mechanism is at play. These results indicate that sliding speed affects the friction primarily through its effect on the adsorption of passivating gas to the sliding surface rather than on the graphitization degree of the DLC surface in vacuum. The results provide strong evidences to support the concept that the primary lubrication mechanism for DLC is passivation of dangling bonds rather than graphitization of the DLC surface.

To better understand the friction mechanism of DLC in vacuum, researchers have studied the friction performance of DLC in vacuum by tailoring sliding interface. They have chosen SiC and Si3N4 with strong adhesion to carbon as well as Al2O3 and ZrO2 with weak adhesion to carbon as mating materials.

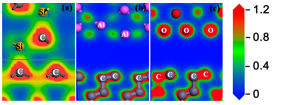

They have showed that the adhesion between mating materials and carbon can greatly affect the vacuum tribological behaviors of DLC films. Converting the conventional but intrinsically adhesive carbonaceous sliding interface into a weak-interacted one, and thereby improving the DLC’s vacuum tribological performance can be realized by sliding against materials with low adhesion to carbon to avoid formation of carbonaceous transfer films. They ascribe the low friction of DLC/Al2O3 and DLC/ZrO2 tribopairs in vacuum to the intrinsically weak interactions between two sliding materials. This simple route to achieve low friction and long wear life for DLC films in high vacuum is desirable for space applications.

The above findings have been published in ACS Appl. Mater. Interfaces(2013, 5, 5889–5893) and Carbon( 2014, 66, 259-266). The work has been received support from the National Natural Science Foundation of China.

Distributions of electron density of optimized (a) SiC(001)/diamond(111) and Al2O3(001)/diamond(111): the slice across (b) Al atoms and (c) O atoms.