The articular cartilage of synovial joint can bear a heavy load while there’s little wear and friction, which proves that a very complicated lubrication system exists in articular cartilage. By studying this lubrication system, the group headed by Prof. ZHOU Feng at the State Key Laboratory of Solid Lubrication of the Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) found that the special structure of the surface of articular cartilage plays an important role for such low friction.

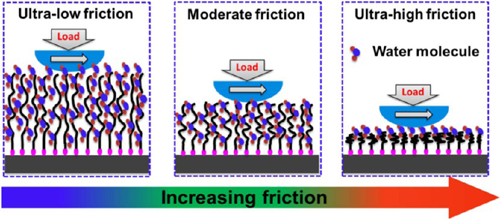

Inspired by this, the researchers grafted polyelectrolyte brushes on solid material surfaces and thus formed a tunable lubrication platform of which the macroscale friction can be dramatically tuned from superior lubrication (μ ~10?3) to ultrahigh friction (μ >1) progressively. They achieved this via exchanging counterions into polyelectrolyte brushes when the surface was sliding against a silicone elastomer ball. The tunable lubrication platform is sensitive and stable, which would be helpful to further understand the lubricating mechanism of polymer brushes and would promote applications of these smart surfaces in microfluidic devices, biosensors, and so on (Macromolecules, 2013, 46, 9368–9379).

Illustration of Correlation between Lubrication and Conformation of Polymer Brushes (Image by ZHOU Feng et al.)

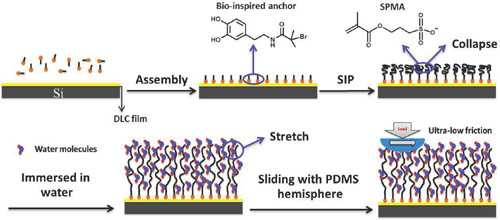

Diamond-like carbon (DLC) film has emerged as a promising material for biomedical applications, but its low tribological properties in air could not be adapted in water and biological fluids. Researchers used mussel-inspired catechol adhesive to functionalize DLC film and then grafted polymer brushes by surface initiated atom transfer radical polymerization (SI-ATRP) to mimic excellent biological lubrication of articular cartilage. Excellent biological lubrication was achieved on the poly(3-sulfopropyl methacrylate potassium salt) brushes (PSPMA) brushes modified DLC films and the modified DLC surfaces showed good compatibility with water and the static WCA value was ~7°. Macroscopic tribological evaluation demonstrates low and stable friction coefficient of polymer brushe modified DLC film in water and biological fluids when sliding with a soft polydimethylsiloxane (PDMS) hemisphere, owing to viscous fluid-like boundary lubricant film being formed by high hydration of polymer chains. In light of these results, the hydrophilic polymer brushes modified DLC film may nevertheless be sufficient for applications in biomedical field, in which friction and wear are often an issue (Adv. Mater. Interf.,2014, DOI: 10.1002/admi.201400035).

Schematic illustration of surface functionalization of DLC and the following friction test. (Image by ZHOU Feng et al.)

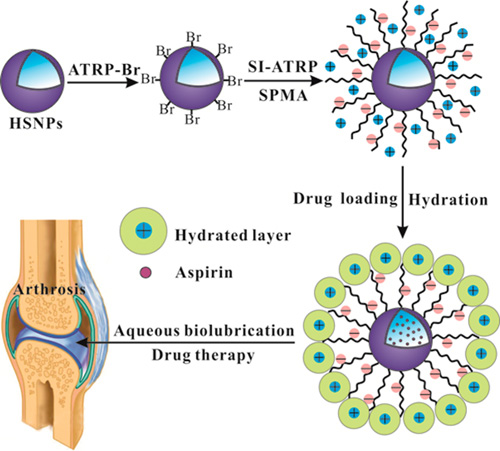

Moreover, by incorporating negatively charged PSPMA brushes-grafted hollow silica nanoparticles (PSPMA-g-HSNPs) with dual functions of hydration lubrication and drug delivery, they prepared core/shell charged polymer brushes-grafted hollow silica nanoparticles (PSPMA-g-HSNPs). Because of the excellent hydration capability of the shells consisting of charged polymer brushes, the functional nanoparticles can achieve a good lubricating effect in aqueous media via hydration lubrication mechanism. The mesoporous hollow silica cores endow the nanoparticles with drug loading?release capability. Aspirin, as a useful drug for treating arthritis, was employed to carry out in vitro drug loading and release studies. The combination of hydration lubrication and drug loading capability renders the core/shell charged polymer brushes-grafted hollow silica particles a promising material for joint lubrication and arthritis treatment (J. Phys. Chem. B, 2014, 118 , 4920–4931).

Graphic abstract of J. Phys. Chem. B, 2014, 118 , 4920–4931 (Image by ZHOU Feng et al.)

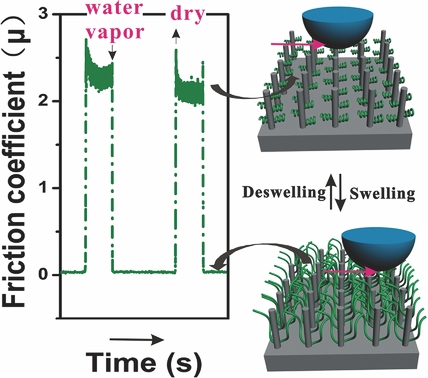

Inspired by the foot of gecko, they also constructed chemically switched friction nano-fibrillar surfaces (SiNWAs-PSPMA & SiNWAs-PMAA arrays) by finely decorating ordered Si nanowire arrays with responsive polymer brushes. As expected, these surfaces sense humidity or pH smartly and show reversible friction switching, based on swelling and shrinking of the polymer brushes, which is successfully monitored by AFM in liquid media (Small,2014,DOI: 10.1002/smll. 201402484).

Graphic abstract of Small,2014,DOI: 10.1002/smll. 201402484 (Image by ZHOU Feng et al.)

The above work has received support from the National Natural Science Foundation of China and Key Research Program of the CAS.