Fluorinated amorphous carbon films exhibit superlow friction under vacuum and are considered the ideal solid lubricating films under high vacuum. However, they are prone to catastrophic failure. To date, their intrinsic failure mechanism has not been well understood yet.

The researchers at the Lanzhou Institute of Chemical Physics of the Chinese Academy of Sciences have revealed the intrinsic failure mechanism of fluorinated amorphous carbon film based on the first-principles calculations, molecular dynamics simulations and compressive stress-strain relation.

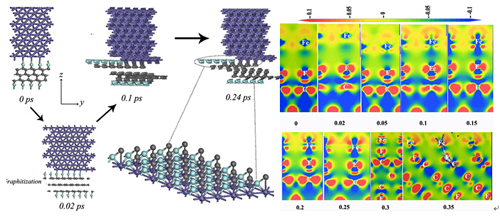

Probing the intrinsic failure mechanism of fluorinated amorphous carbon film based on the first-principles calculations and molecular dynamics methodology (Image by LICP)

They have demonstrated that the plastic deformation induced graphitization causes strong adhesion between two contacted surfaces under vacuum, which leads to the failure of the films. Under elastic deformation regions, the low friction would be obtained when the tribochemical reaction and graphitization concur.

To verify their calculated results, they have conducted sliding contact experiments and studied tribological properties of iron and fluorinated amorphous carbon surfaces under vacuum. The results show that the failure of the film is directly attributed to strong adhesion resulting from high degree of graphitization of the film, which is consistent with the calculated results.

Their further studies show that the responses of bond lengths during the strain processes significantly influence the mechanical properties of the system. It is found that the C-C bonds and C-F bonds at the interface are very sensitive to the compressive strain and chemical environment. When the compressive strains increases or the bond-forming state of the pairing material is changed, the distribution of interfacial charge related to friction experiences dramatic change and causes the bond length and energy of C-C and C-F to change, which influences the interfacial stability and adhesion.

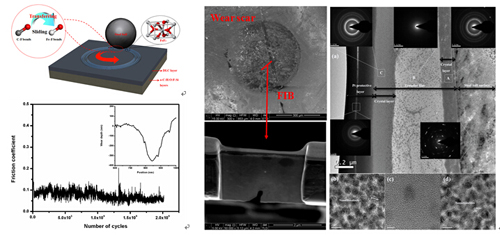

Based on their understanding of the failure mechanism, they have prolonged wear life of amorphous carbon films under vacuum by composition design and construction of interfacial multi-layered structure. They have fabricated F and Si co-doped amorphous carbon film on stainless steel substrates using a plane hollow cathode plasma-enhanced chemical vapor deposition method. The amorphous carbon film acting as a lubricant layer containing hydrogen, oxygen, fluorine and silicon (a-C:H:O:F:Si) exhibited low friction (~0.1), ultra-low wear rate (9.0 × 10–13 mm3 N–1 mm–1) and ultra-long wear life (>2 × 106 cycles) under high vacuum.

A near-wearless and extremely long lifetime amorphous carbon film under high vacuum by composition design and construction of interfacial multi-layered structure (Image by LICP)

The reason for the excellent friction and wear behavior is the formation of FeF2 nanocrystallites induced by tribochemical reaction during sliding. The formation of FeF2 was thermodynamically and structurally stable, which ensured the superior tribological properties under high vacuum.

The understanding of the failure mechanism of fluorinated amorphous carbon film in vacuum and prolonging of their wear life is desirable for their potential space applications.

The work has received support from the National Nature Science Foundation of China and the Nature Science Foundation of Gansu Province of China. The work has been published in Scientific Reports (2015, 5, 9419;2015, 5, 11119; 2015,5,12734).

Contact:

LU Zhibin

State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou 730000, China

E-mail: zblu@licp.cas.cn