Thermal spraying is an important technique in surface engineering. Just as the name implies, thermal spraying is to spray a kind of coating onto the surface of a substrate or component. Such coating can protect or improve the performance of the component. And the coating can be metallic, ceramic, plastic etc. Among various ceramic coatings, Al2O3 and ZrO2 coating has been widely applied. However, ceramic coating, restricted by unsatisfactory lubrication property, is not so popular in high-end equipment manufacturing.

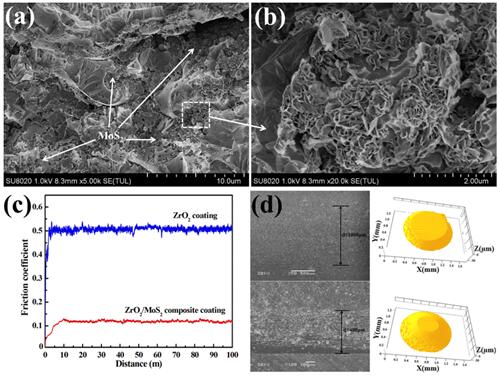

But here comes the good news: ceramic coating becomes optimized, more durable and practical in manufacturing industry, thanks to its improved tribological performance. The Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) has made continuous progress in improving friction property of ceramic coating. They have in-situ synthesized lamellar-like MoS2 in the pores and micro-cracks of ZrO2 ceramic coatings using hydrothermal method coupled with vacuum impregnation, which perfectly resolves the friction problem of ceramic coating. This lamellar-like MoS2 works as the lubricant, on one hand, to mitigate the friction between the coating and substrate, and on the other hand protects substrate surfaces from being worn.

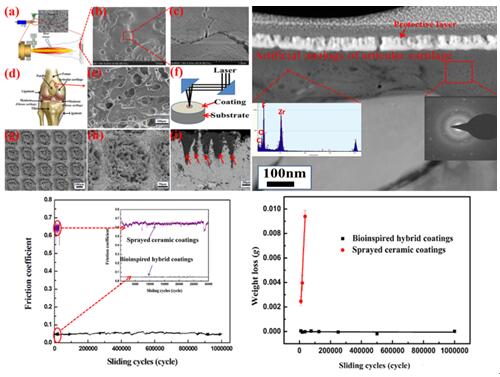

More importantly, based on previous study, LICP researchers have developed a bio-inspired smart coating with superior tribological performance. This smart coating can maintain a low coefficient of friction under a large range of sliding speeds and applied loads. When a high load of 1.4GPa is applied, the coefficient of friction can be kept at <0.065. Besides, after repeated friction tests, both the smart coating itself and metal substrate experience almost zero weight losses, which means that this smart coating can do a great job in protecting coating and substrate from abrasion.

As a result, with its improved tribological performance, ceramic coating is expected to receive broader application and play a bigger role in surface engineering. LICP researchers have published their finding in Ceramics International, 2017, 43(9): 6976-6986, Materials Letters193 (2017) 199-202 and ACS Applied Materials & Interfaces(DOI: 10.1021/acsami.7b03986).

This project has received long-term support by Youth Innovation Promotion Association of the CAS (2014378) and Category A Talent Training Project of Young Scholars in Western China under West Light Foundation of the CAS.

Tribological properties of the ZrO2/MoS2 composite coating (Image by LICP)

Bio-inspired coating with excellent tribologcial properties (Image by LICP)

Contact :

HOU Guoliang; ZHAO Xiaoqin; CHEN Jianmin; ZHOU Huidi; AN Yulong

State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou,

E-mail: houguoliang415514@163.com; zhaoxiaoqin@licp.cas.cn; hdzhou@lzb.ac.cn; chenjm@licp.cas.cn; csuayl@sohu.com