Low surface energy coating materials have crucial application prospects in fluid drag reduction, anti-fouling, self-cleaning, and anti-icing due to their unique wettability.

The surface and interface group from the Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) has been devoted to relevant research in this field, and recently, progress has been made.

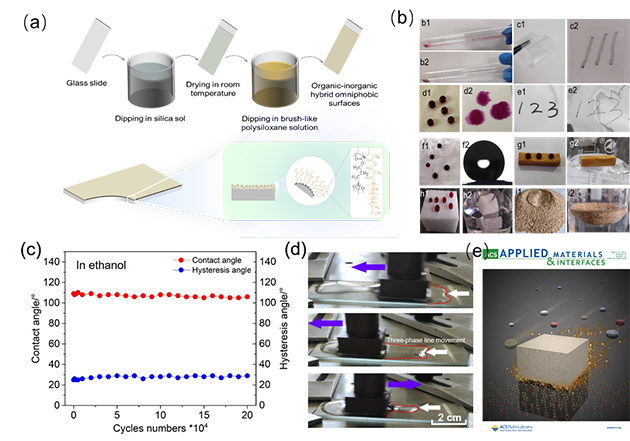

In recent years, slippery liquid infused porous surface (SLIPS) that were inspired by nepenthes plants has become a trending research topic. However, this SLIPS material has poor wear resistance, and lubricant molecules were easily lost, which led to poor durability in SLIPS. To solve these problems, the researchers have designed and prepared a brush-like polysiloxane lubricant macromolecule that contains an "anchor" group. The polysiloxane lubricant molecule was able to graft onto solid surface by covalent bonding, and at the same time, an inorganic interlayer was introduced into the coating system to increase bonding strength. The mechanical wear resistance of coating surface was greatly improved, and surface wettability was almost unchanged after 30,000 friction cycles under 100 KPa. In addition, the coating can be applied to various substrates to endow those substrates with hydrophobic property (Prog. Org. Coat., 2021, 154, 106171, Figure 1a-b).

Then, the polysiloxane chains of the coating were replaced by perfluorinated polyether segments, thus obtaining a superior wear resistance. Hydrophobicity decreased by less than 5% and stain resistance remained unchanged after 200,000 friction cycles under 100 KPa in an organic solvent (Figure. 1c-d).

This work was published on ACS Appl. Mater. Interfaces as a cover page (ACS Appl. Mater. Interfaces 2021, 13, 14562, Figure 1e) .

Figure 1. Brush-like self-lubricating amphiphobic coating.

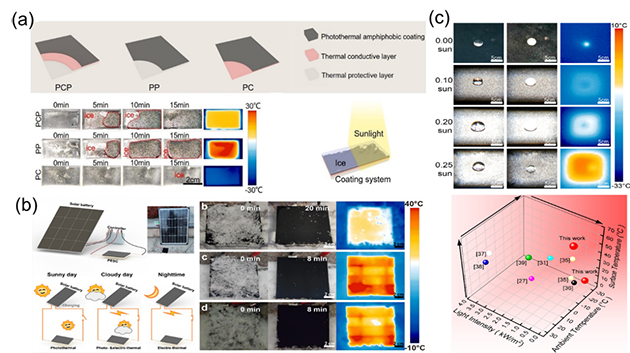

Superhydrophobic coating inspired by the lotus leaf has obvious anti-icing behavior in specific conditions, but this anti-icing property will be lost in a damp environment. The superhydrophobicity would be further damaged when deiced via external mechanical force. To solve these problems, the researchers have prepared a superamphiphobic coating using fluorocarbon nanotubes and acrylic resin. Taking advantage of the photo-thermal performance of carbon nanotubes, the coating was self-heated to achieve anti-icing and de-icing when irradiated by sunlight. In the coating system, the three layers of the coating structures include the photothermal layer, thermal conductivity layer, and insulation layer and were designed to improve photothermal deicing efficiency. The entire surface was heated to deice just a part of the coating area exposed to sunlight (ACS Appl. Mater. Interfaces, 2020, 12, 46981, Figure. 2a). The newly prepared coatings has both electrothermal and photothermal properties, which makes the coating achieveanti-icing and deicing that lasted all day possible (Adv. Mater. Tech., 2021, 6, 2100371, Figure. 2b).

To avoid the heat loss, the researchers also prepared superhydrophobic macroporous xerogel to realize thermal-regulation. To take advantage of the porous heat insulation property, the heat was located on the light irradiation area, which greatly improved the photothermal efficiency of the material. Water droplets will never freeze under 0.25 sun in –30℃ on the surface (ACS Appl. Mater. Interfaces 2021, 13, 37609, Figure. 2c).

Figure 2. Photo-/electric-thermal superhydrophobic anti-icing coating.

Figure 3. Major anti-icing material strategies.

Based on the aforementioned research, the team has written a review article entitled Material Strategies for Ice Accretion Prevention and Easy Removal published in the ACS Materials Letter (ACS Mater. Lett. 2022,4, 246-262, Figure 3). From the material perspective, three kinds of anti-icing strategies, namely passive, active, and a combination of active and passive anti-icing strategies are summarized.

Researchers have applied 6 national invention patents with all 6 items have being authorized (ZL 201811398503.3,ZL 201810449961.9,ZL 202010505684.6 and ZL 202110702491.4).

The research was supported by the National Science Foundation of China, Gansu Civil-military Integration Office, CRRC Corporation Limited, and Yantai Zhongke Advanced Materials and Green Chemical Institute.

Contact:

Wu yang

Email: yangwu@licp.cas.cn

Lanzhou Institute of Chemical Physics