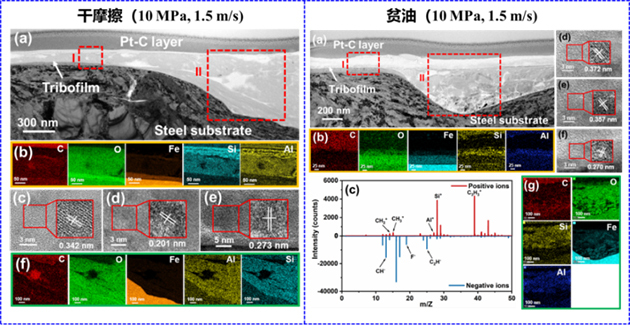

The Polymer Nanocomposites Research Group at the Lanzhou Lubricating Materials and Technology Innovation Center of LICP, in collaboration with the Institute of Composite Materials in Germany, has carried out in-depth research on the theories and technologies of intelligent solid lubrication for polymers. The team uncovered the construction mechanism of a transfer film with self-optimizing lubrication performance (Fig. 1), tackled key links across the entire industrial chain from formula development and bench testing to industrial application, and developed polymer solid lubricating materials for wind power plain bearings.

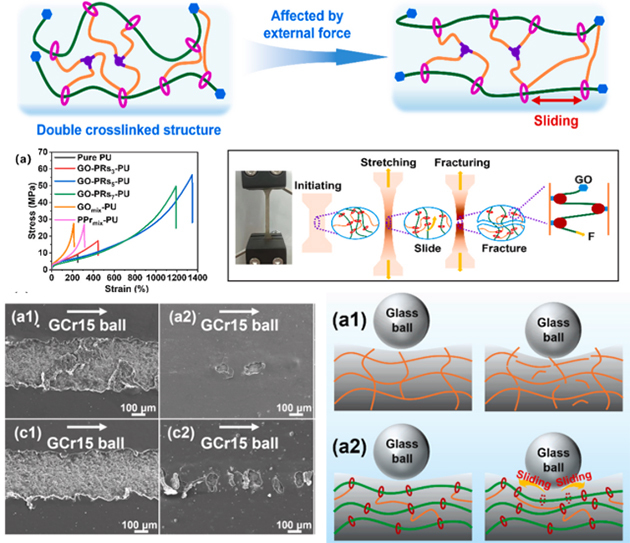

During the project implementation, the Institute of Composite Materials in Germany was responsible for technical work including industrial-grade tribological testing. Through this international cooperation, the two sides realized the intelligent regulation of the nanostructure at the friction pair interface under multiple working conditions (Fig. 2), breaking through the technical bottlenecks of solid lubrication technology for wind power plain bearings operating under complex working conditions.

Relevant research findings have been published in Composites Part B: Engineering, ACS Sustainable Chemistry & Engineering and ACS Applied Materials & Interfaces.

Fig. 1 Construction of transfer film with self-optimizing lubrication performance.(Image by LICP)

Fig. 2 Adaptive friction and wear reduction mechanism based on stress dissipation at the friction interface.(Image by LICP)