Abstract

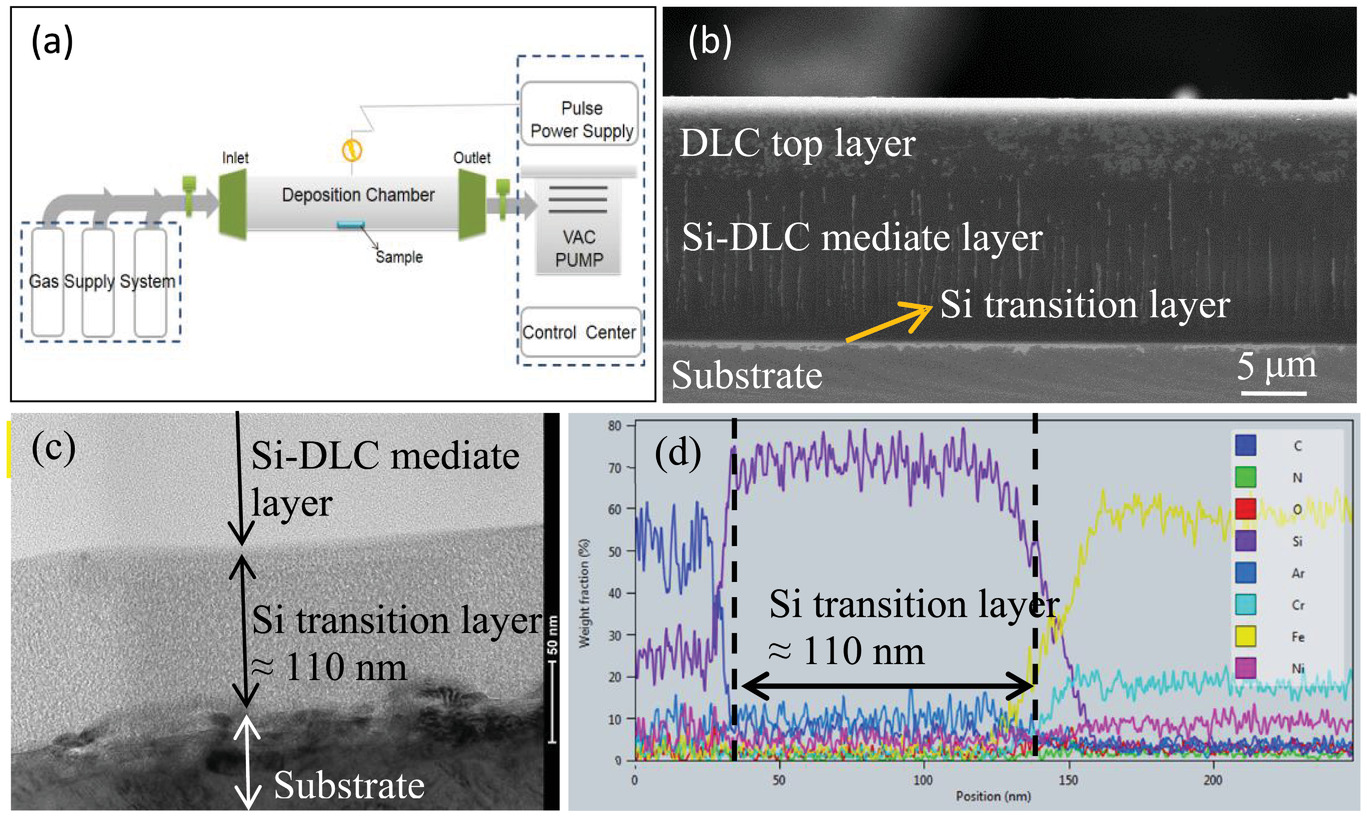

Thick diamond-like carbon (DLC) coatings with different silicon (Si) transition layer thickness are deposited by hollow cathode plasma immersion coating technology. The results show that the internal stress of the coating can be tuned by changing the deposition time of Si transition layer, thereby obtaining good adhesion strength. Friction and wear results show that all coatings have good tribological properties. The coating with 8 min Si transition layer (Si-8) demonstrates the lowest friction coefficient (mu approximate to 0.03), even achieves ultralow friction (mu approximate to 0.008) for a short time. However, the wear rate of Si-8 coating is found to be the largest (2.1 x 10(-16)m(3)(N m)(-1). The low friction coefficient of Si-8 coating is related to its high degree of graphitization, complete transfer film and fine wear debris. In contrast, the Si-16 coating has the lowest wear rate of about 5.6 x 10(-17)m(3)(N m)(-1)with a relatively high friction coefficient (mu approximate to 0.1). This is due to its high hardness and the formation of a nano-twisted double helix carbon debris during the friction process. This nano-twisted double helix structure can consume additional plastic deformation energy, while reducing the interface contact area and increasing the interface bearing capacity, thereby improving the wear resistance of the thick DLC coating.

KeyWords Plus:HYDROGENATED AMORPHOUS-CARBON; SUPERLOW FRICTION; DLC COATINGS; FILMS; SUPERLUBRICITY; DEPOSITION; TRIBOLOGY

Published in ADVANCED MATERIALS INTERFACES;10.1002/admi.202000857,AUG 2020