Abstract

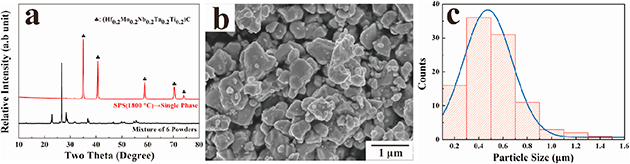

The single-phase (Hf0.2Mo0.2Nb0.2Ta0.2Ti0.2)C ceramics with uniform composition have been prepared by spark plasma sintering. The microstructure, mechanical and tribological properties were studied. The experimental results indicate that grain size and densification degree determine their mechanical properties. Meanwhile, the high temperature deteriorates their hardness and fracture toughness. The HEC3 sintered at 2000 degrees C exhibits excellent mechanical properties and wear resistance. Its hardness and fracture toughness are 18.5 GPa and 4.2 MPam(1/2) at 25 degrees C, respectively. And its wear rate is as low as 10(-5)-10(-7) mm(3)/Nm at 25-600 degrees C. The outstanding wear resistance benefits from the synergistic effect of the generated tribo-film and excellent mechanical properties. This material is expected to be a novel kind of high-temperature materials for tribological application.

The single-phase (Hf0.2Mo0.2Nb0.2Ta0.2Ti0.2)C ceramics with uniform composition have been prepared by spark plasma sintering. The microstructure, mechanical and tribological properties were studied. The experimental results indicate that grain size and densification degree determine their mechanical properties. Meanwhile, the high temperature deteriorates their hardness and fracture toughness. The HEC3 sintered at 2000 degrees C exhibits excellent mechanical properties and wear resistance. Its hardness and fracture toughness are 18.5 GPa and 4.2 MPam(1/2) at 25 degrees C, respectively. And its wear rate is as low as 10(-5)-10(-7) mm(3)/Nm at 25-600 degrees C. The outstanding wear resistance benefits from the synergistic effect of the generated tribo-film and excellent mechanical properties. This material is expected to be a novel kind of high-temperature materials for tribological application.

Author Keywords:High-entropy carbide; Mechanical properties; Tribological behaviors; Elevated temperature

Published in TRIBOLOGY INTERNATIONAL,Volume 157;10.1016/j.triboint.2021.106883,MAY 2021