Abstract

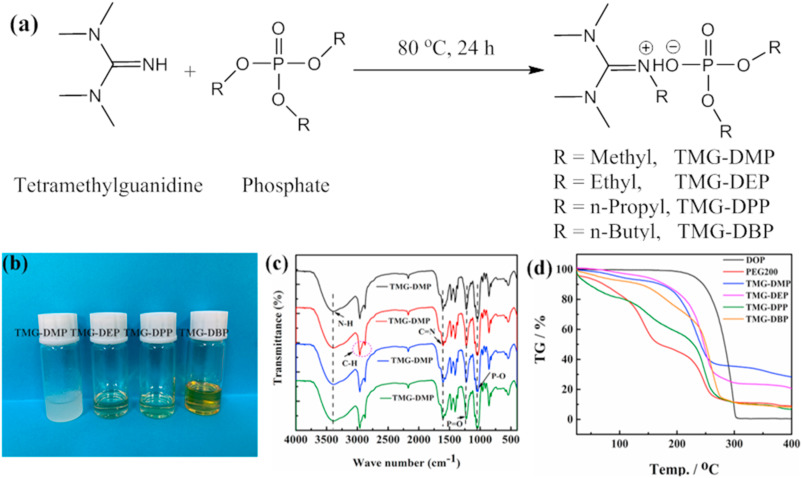

Four guanidine-phosphate ionic liquids (ILs) were synthesized successfully and the antiwear property was tested as additives with various concentrations in different basic oils, di(2-ethylhexyl) phthalate (DOP) and polyethylene glycogen (PEG200), respectively. The results showed that all four ILs had excellent friction-reducing and antiwear property under high load (300 N) both at room temperature and 100 degrees C. Through analyzing the tribological morphology, chemical composition and tribofilm microstructure of wear scars surface by SEM, 3D profile, XPS and FIB-TEM, the antiwear mechanism of ILs was revealed. In DOP, the enhanced antiwear property after adding additives was attributed to both form electrostatically adsorbed layer to avoid the direct contact of friction pairs and the synergy effect of phosphine and nitrogen element to produce a chemical-film (about 13.5 nm) on the metal substrate. However, in PEG200, the excellent antiwear property after adding additives was due to the guanidine ILs effectively reduce the interaction of base oil molecules under high load because of the proton-like structure of guanidine-phosphate ILs. This will help to guide the design of new lubrication additives according to basic oils.

Keywords Plus:GLOBAL ENERGY-CONSUMPTIONTRIBOLOGICAL PERFORMANCEFRICTIONSURFACE

Published in TRIBOLOGY INTERNATIONAL,Volume 160;10.1016/j.triboint.2021.106942,AUG 2021