Abstract

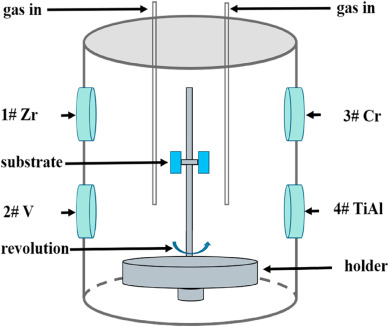

High entropy ceramics (HECs) films (TiCrZrVAl)N were deposited on Inconel 718 alloys by multi-arc ion plating (MAIP) equipment at different nitrogen flow ratios Rn--N2/(N2+ Ar). The effects of Rn (0%, 20%, 50%, 80%, 90%) on the evolution of microstructure, mechanical properties, and tribological properties of films were systematically studied. The films deposited at low Rn exhibited an amorphous structure and smooth cross-section, whereas the films at Rn of 50% and higher showed a face-centered-cubic (FCC) NaCl-type structure with loose columnar cross-section. With the increase of Rn, the content of the N element increased, the Cr element decreased, and other elements (Ti, Zr, V, Al) nearly remained stable. The films' hardness and elastic modulus increased gradually and reached the maximum value of 31.08 +/- 1.81 GPa and 387.66 +/- 12.49 GPa, respectively, when Rn was 80%. The films deposited at Rn of 20% invalided easily in tribology tests, whereas the films prepared under Rn exceeded 20% presented outstanding wear resistance and obtained the minimum wear rate of 7.4x10-16 m3/(N.m) when Rn is 80%.

Keywords Plus:MECHANICAL-PROPERTIESTRIBOLOGICAL BEHAVIOROXIDATION RESISTANCETHERMAL-STABILITYCOATINGSNITRIDEALLOYSTINCARBIDEENERGY

Published in CERAMICS INTERNATIONAL,Volume 47;1016/j.ceramint.2021.05.198,SEP 1 2021