Abstract

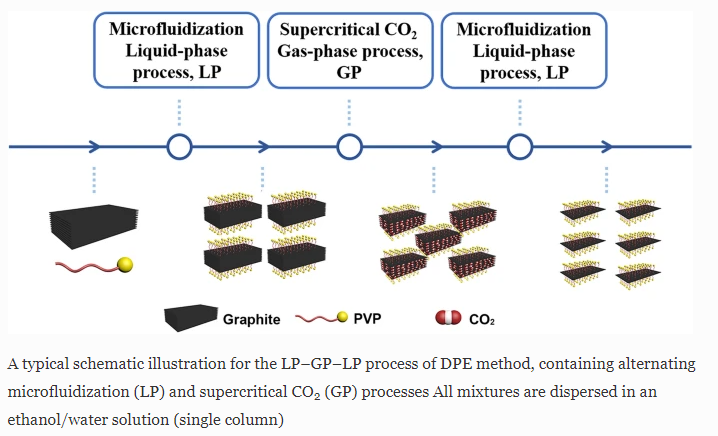

Traditional "top-down" methods for graphene preparation, like micromechanical cleavage and ultrasound methods, usually cannot preserve both efficiency and quality simultaneously. Herein, we provide an environmental-friendly graphene exfoliating method with high efficiency and high quality that combines the microfluidization process (liquid phase) and supercritical carbon dioxide process (gas phase), namely the dual-phase exfoliating (DPE) method. The combination of effective tangential force (shearing force) and normal force (push and pull), which are originally from microfluidization and supercritical carbon dioxide process, respectively, maximizes the exfoliating efficiency. The DPE method offers a high yield of up to 70.25% for graphene preparation (941.04 g per day theoretically), while the graphene sheets could remain single or a few layers (> 80%) and around micron size. By molecular dynamic simulations, it is theoretically proved that carbon dioxide can intercalate between graphite layers and expand the interlayer spacing under supercritical conditions. This DPE method, by combining the advantages of different phase processes, provides an ideal process design perspective for large-scale preparation of other 2D materials.

Keywords Plus:FEW-LAYER-GRAPHENETHERMAL-CONDUCTIVITYSCALABLE PRODUCTIONSHEAR EXFOLIATIONSINGLE-LAYERGRAPHITENANOSHEETSFORCEWATERCO2

Published in JOURNAL OF MATERIALS SCIENCE,Volume56;10.1007/s10853-021-05903-4,OCT 2021