Abstract

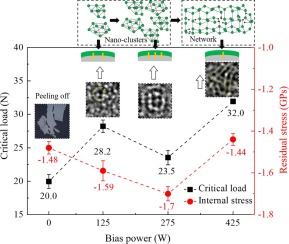

Different nanostructures of the a-Si:H interlayer were designed by tuning the bias power to reveal the impacts on the adhesion of thick DLC coatings prepared by PECVD. Besides the formation of stable Si-Fe bonds, the a-Si:H interlayer transformed from nano-porous structure into tiny clusters and finally into crosslinked network by raising the bias power from 125 to 425 W. The interlayer with crosslinked network promoted the formation of more Fe-Si dangling bonds at the bonding layer as well as better structure matching with top layers, resulting in the highest adhesion strength of 32 N and the lowest internal compressive stress of -1.44 GPa. When amounts of tiny clusters were formed in the interlayer at 275 W, the lowest adhesion strength of 23.5 N was obtained. This was due to the low chemical reactivity of tiny clusters hindered the formation of the Si-Fe bonds.

Different nanostructures of the a-Si:H interlayer were designed by tuning the bias power to reveal the impacts on the adhesion of thick DLC coatings prepared by PECVD. Besides the formation of stable Si-Fe bonds, the a-Si:H interlayer transformed from nano-porous structure into tiny clusters and finally into crosslinked network by raising the bias power from 125 to 425 W. The interlayer with crosslinked network promoted the formation of more Fe-Si dangling bonds at the bonding layer as well as better structure matching with top layers, resulting in the highest adhesion strength of 32 N and the lowest internal compressive stress of -1.44 GPa. When amounts of tiny clusters were formed in the interlayer at 275 W, the lowest adhesion strength of 23.5 N was obtained. This was due to the low chemical reactivity of tiny clusters hindered the formation of the Si-Fe bonds.

Keywords Plus:DIAMOND-LIKE CARBONHYDROGENATED AMORPHOUS-CARBONPIII-AND-DION-IMPLANTATIONFILMS DEPOSITIONINTERNAL-STRESSSTAINLESS-STEELLOW-FRICTIONMICROSTRUCTURESUPERLUBRICITY

Published in APPLIED SURFACE SCIENCE,Volume565;10.1016/j.apsusc.2021.150539,NOV 1 2021