Abstract

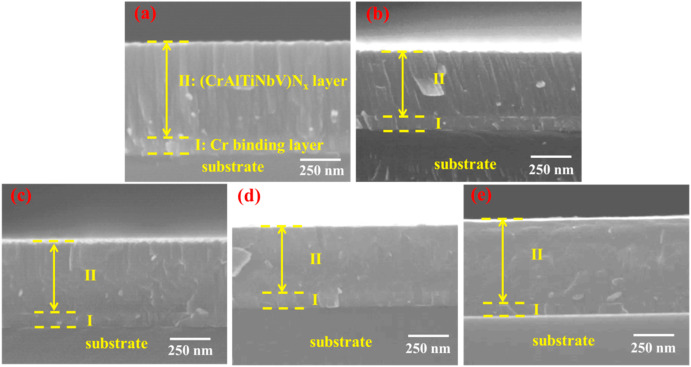

The (CrAlTiNbV)Nx coatings are fabricated by controlling the substrate bias via magnetron sputtering method. Under low substrate bias, the coating tends to form a loose columnar crystal structure with (200) preferred orientation. However, when the substrate bias increases, the coating transforms into a dense nanocrystalline structure, and the (111) orientation is enhanced. As the substrate bias increases, the residual stress and hardness of the coating gradually increase, while the adhesion strength decreases slightly. Friction tests show that the coating possesses the lowest average friction coefficient (about 0.06) and wear rate (8.7 x 10-9 mm3/N.m) in 4050# aviation lubricant, which is achieved under the substrate bias of -96 V and -126 V, respectively.

Keywords Plus:SUBSTRATE BIASTHIN-FILMSDEPOSITIONTEMPERATURE

Published in CERAMICS INTERNATIONAL,Volume 47;10.1016/j.ceramint.2021.06.156,OCT 1 2021