Abstract

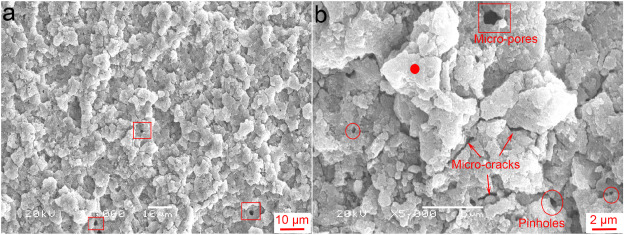

The plasma electrolytic fluorination (PEF) process was conducted on 6061 Al alloy in the NH4F-EG non-aqueous electrolyte at room temperature. The microstructure and composition of the resultant coating were characterized by SEM, EDS, XRD and XPS. Also the coating growth and plasma discharge behavior were investigated by means of a well-designed jig, digital camera and OES, in order to understand the process characteristics. Results showed that the coating was dominantly composed of AlF3, and characterized by a flake-like microstructure accompanying with some micro-pores and numerous micro-cracks. The internal of the coating was porous with a compact barrier layer near the substrate/coating interface. The fluorination of the substrate contributed the inward growth of the coating. PEF discharge sparks were characterized by tiny size and weak intensity during the whole process, of which the plasma electron temperature was about (3510 +/- 110) K. Also, the discharge behavior and coating growth mechanism of the PEF process on Al alloy were discussed.

Keywords Plus:CERAMIC COATINGSALUMINUM-ALLOYSCORROSION BEHAVIOROXIDATION COATINGSMAGNESIUM ALLOYTITANIUMSURFACEMICROPHASEFILM

Published in CERAMICS INTERNATIONAL,Volume 47;10.1016/j.ceramint.2021.07.148,NOV 1 2021