Abstract

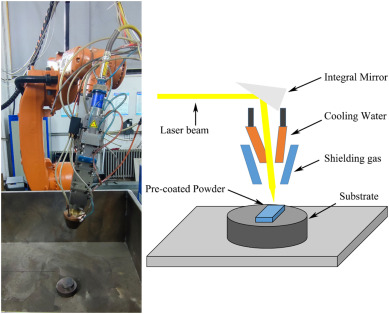

In order to study the effect of Cr content on the glass forming ability (GFA) and mechanical properties of Fe-based amorphous composite coatings, and to prepare the Fe-based amorphous composite coatings with high hardness and wear resistance. Fe-Cr-Mo-B-Si amorphous composite coatings were prepared by laser cladding technology with different Fe to Cr ratio. The phase composition and microstructure were studied by X-ray diffraction (XRD), scanning electron microscope (SEM), energy dispersive spectroscopy (EDS) and transmission electron microscope (TEM) techniques. Vickers indenter, nano-indentor and friction testing machine were used to investigate the mechanical properties and wear resistance of the amorphous coatings. The XRD patterns results show that the phase composition and the content of amorphous changed obviously, and the microstructure transformed clearly from equiaxed dendrite structure to the mixed structure of crystal and amorphous with the content of Cr increases in a restriction range. It was found that the coating showed the best glass forming ability (GFA) when the Fe to Cr ratio was 0.33. The coating was mainly composed of Fe-based solid solution, amorphous and a small number of intermetallic compounds. Appropriate content of Cr can effectively inhibit the formation of intermetallic compounds and decrease the effect of dendrite orientation growth. The high amorphous content makes the coating exhibit excellent microhardness (1200 HV) and wear resistance (2.7 x 10(-6) mm(3)/ (Nm)). At this time, slight abrasive wear is the mainly wear mechanism of Fe-based amorphous composite coatings with the elements component of Fe43.55Cr21.45Mo15B10Si10 (atm. %) at room temperatures.

In order to study the effect of Cr content on the glass forming ability (GFA) and mechanical properties of Fe-based amorphous composite coatings, and to prepare the Fe-based amorphous composite coatings with high hardness and wear resistance. Fe-Cr-Mo-B-Si amorphous composite coatings were prepared by laser cladding technology with different Fe to Cr ratio. The phase composition and microstructure were studied by X-ray diffraction (XRD), scanning electron microscope (SEM), energy dispersive spectroscopy (EDS) and transmission electron microscope (TEM) techniques. Vickers indenter, nano-indentor and friction testing machine were used to investigate the mechanical properties and wear resistance of the amorphous coatings. The XRD patterns results show that the phase composition and the content of amorphous changed obviously, and the microstructure transformed clearly from equiaxed dendrite structure to the mixed structure of crystal and amorphous with the content of Cr increases in a restriction range. It was found that the coating showed the best glass forming ability (GFA) when the Fe to Cr ratio was 0.33. The coating was mainly composed of Fe-based solid solution, amorphous and a small number of intermetallic compounds. Appropriate content of Cr can effectively inhibit the formation of intermetallic compounds and decrease the effect of dendrite orientation growth. The high amorphous content makes the coating exhibit excellent microhardness (1200 HV) and wear resistance (2.7 x 10(-6) mm(3)/ (Nm)). At this time, slight abrasive wear is the mainly wear mechanism of Fe-based amorphous composite coatings with the elements component of Fe43.55Cr21.45Mo15B10Si10 (atm. %) at room temperatures.

Keywords Plus:BULK METALLIC GLASSESFORMING ABILITYMAGNESIUM ALLOYSIMICROSTRUCTURENANOINDENTATIONEVOLUTIONBEHAVIORHEAT

Published in SURFACE & COATINGS TECHNOLOGY,Volume 423;10.1016/j.surfcoat.2021.127520,OCT 15 2021