Abstract

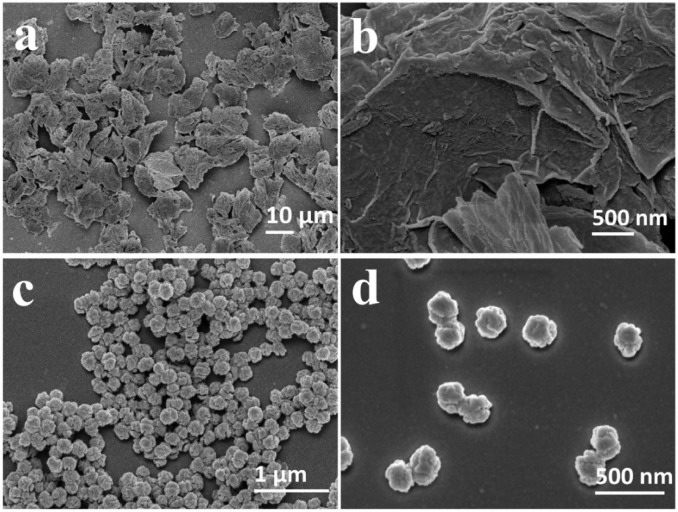

Taking fluorinated graphene (FG) and polytetrafluorethylene (PTFE) as the typical models, this work aims to clarify the influences of carbon-skeleton structure and C-F bond strength on their tribological performance and lubrication mechanism under extreme-pressure condition. As oil additives, the load-bearing capacity of PAO-6 increases from 300 N to 600 N with FG and 400 N with PTFE. Compared with the situation with the PTFE sub-microspheres, the wear rate of PAO-6 with FG nanosheets reduces by about 40%. Proved by the apparent difference in tribofilm formation ability of FG and PTFE, it is believed that the higher reactivity of the C-F bond and adsorption ability of two-dimensional carbon-skeleton play a crucial role in FG's excellent tribological performance.

Keywords Plus:ENERGYFLUOROGRAPHENELUBRICATIONCONSUMPTIONMECHANISMSURFACES

Published in TRIBOLOGY INTERNATIONAL,Volume 165;10.1016/j.triboint.2021.107250,JAN 2022