Abstract

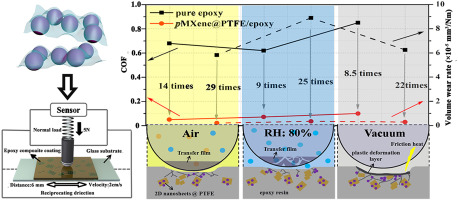

In this work, a novel lubricating additive was designed and synthesized via self-assembling of wrapped PTFE nanoparticles by exfoliated MXene nanosheets. Then the pMXene@polytetrafluoroethylene (pMXene@PTFE) hybrid was introduced into epoxy coating and painted to substrate. The composite with PTFE would effectively alleviate the oxidation of MXene sheets. The research results show that the epoxy-based composite coating has excellent friction-reduction and wear-resistance properties in dry air, humid air (RH = 80%), and vacuum (3 x 10(-5) Mbar) environments, achieving multi-environmental stability binary composite coating. The performance improvement of composite coating mainly depends on the following points: (a) the lubricating synergistic effect of MXene sheets and PTFE hybrid additive with core-shell structure; (b) the good dispersibility and adhesion of composite additive in the epoxy matrix; (c) the formation of protective film on the upper counterpart. The obtained friction results demonstrate that self-assembled pMXene@PTFE epoxy coatings greatly enhance the lubricating and antiwear properties in multiple environments, establishing a promising platform for the design and application of novel high-performance additive with environmental insensitivity. (C) 2021 Elsevier Ltd. All rights reserved.

Keywords Plus:TRIBOLOGICAL PROPERTIESFRICTION PERFORMANCEGRAPHENE OXIDEWEARPTFECOMPOSITESHUMIDITYMXENESWATER

Published in CARBON,Volume184,12-23,10.1016/j.carbon.2021.07.102;OCT 30 2021