Abstract

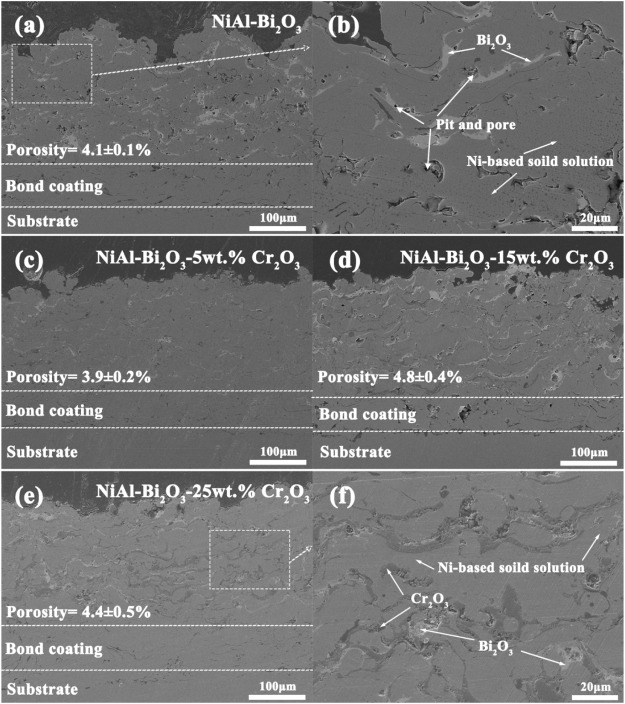

Existing atmospheric plasma sprayed NiAl-20 wt% Bi2O3 composite coating displays the poor mechanical properties, thus this paper investigated the influence of adding different fractions of Cr2O3 on microstructural alteration and tribological behavior of NiAl-20 wt% Bi2O3 coating at RT, 400 degrees C and 800 degrees C. Desirable lubrication of NiAl-Bi2O3-Cr2O3 coating primarily resulted from Bi2O3 by its virtues of soft, low shear stress, and diffusion with temperature stimulus. Instead, Cr2O3 addition improved the wear resistance significantly, which was attributed to the increase of hardness and plastic deformation resistance, especially when 15 wt% Cr2O3 was adopted. The relationship between the Cr2O3 addition and relevant composition migration and mechanical transition on the worn surface at varying temperatures was further researched in this work.

Existing atmospheric plasma sprayed NiAl-20 wt% Bi2O3 composite coating displays the poor mechanical properties, thus this paper investigated the influence of adding different fractions of Cr2O3 on microstructural alteration and tribological behavior of NiAl-20 wt% Bi2O3 coating at RT, 400 degrees C and 800 degrees C. Desirable lubrication of NiAl-Bi2O3-Cr2O3 coating primarily resulted from Bi2O3 by its virtues of soft, low shear stress, and diffusion with temperature stimulus. Instead, Cr2O3 addition improved the wear resistance significantly, which was attributed to the increase of hardness and plastic deformation resistance, especially when 15 wt% Cr2O3 was adopted. The relationship between the Cr2O3 addition and relevant composition migration and mechanical transition on the worn surface at varying temperatures was further researched in this work.

Keywords Plus:WEARTEMPERATUREBEHAVIORMICROSTRUCTUREINDENTATIONSURFACENICKELDEFORMATIONFRICTION

Published in SURFACE & COATINGS TECHNOLOGY,Volume 427;10.1016/j.surfcoat.2021.127818,DEC 15 2021