Abstract

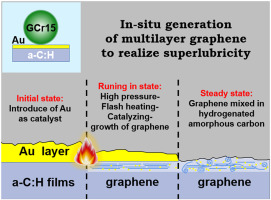

Though amorphous carbon films are kinds of most distinguished lubricant materials, the friction coefficients of commercial amorphous carbon films are in the range of 0.05-0.40. To reduce the friction coefficients of those amorphous carbon films from the order of 0.01 to 0.001 range is still a big challenge. In order to solve the problem, in present work, a new strategy, called catalytic superlubricity, is proposed and carried out to achieve superlubricity by in-situ formation of graphene via introducing gold onto hydrogenated amorphous carbon (Au@a-C:H) film during friction. The results show that mulilayer graphene along with oriented polyolefin-like structures are formed due to the catalysis of Au nanoparticles, which is embedded in amorphous carbon matrix. Furthermore, the density functional theory calculations indicates that interlayer binding energy between graphene and the hydrogenated amorphous carbon (aC:H) films' surface is comparable to that between graphene layers, resulting in low interfacial interactions between sliding interfaces for low friction. Then, the low interfacial interactions lead to superlubricity with a friction coefficient of 0.003. This study opens up a new routing for facile and scale up fabrication of superlubricant a-C:H films in industrial applications. (c) 2021 Elsevier Ltd. All rights reserved.

Keywords Plus:DIAMOND-LIKE CARBONGENERALIZED GRADIENT APPROXIMATIONELECTRON LOCALIZATIONNANOPARTICLESGRAPHITEMETALS

Published in CARBON,Volume 186;10.1016/j.carbon.2021.10.016,JAN 2022